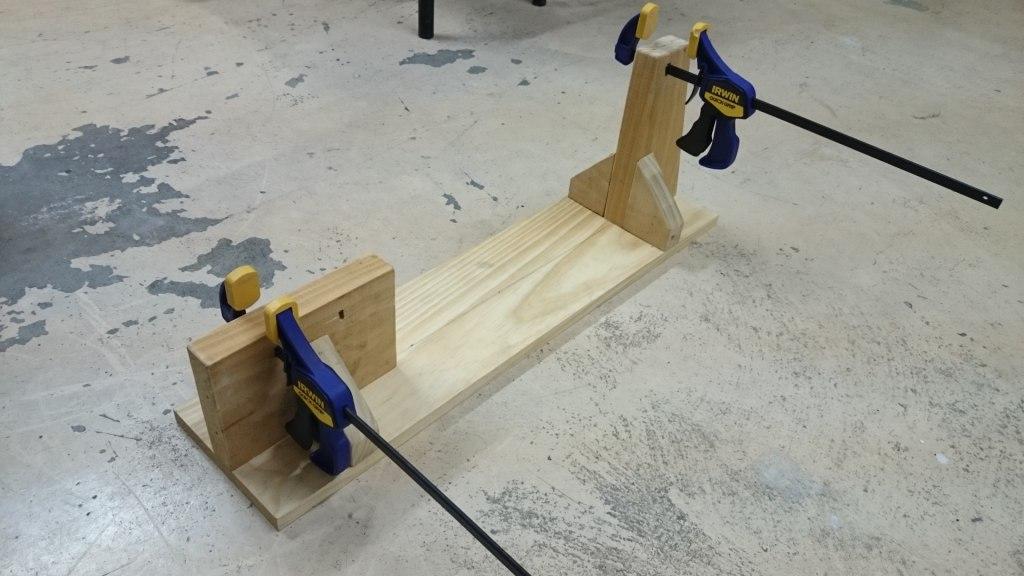

Procedure:

- Measure the worktable.

- Measure out and cut out the jaws to length.

- Align and drill the pipe holes.

- Mount the pipe clamps to the jaws.

- Mount jaws to the bench using nuts and hex head bolts for mounting a bench vise.

How do I install the vise?

The easiest installation entails making spacer blocks to set the tops of the metal jaws below the bench surface while screwing the vise to the underside of a bench. To begin, drive the roll pin from the end of the vise screw, remove the connecting bracket and the front jaw, and then degrease the vise of its protective coating.

How do you mount a vice on an inverted benchtop?

Place the rear jaw upside down on the inverted benchtop and measure how far the top of the jaw extends below the bottom. 14″ for a 7″ vise, 12″ for a 10″ vice (The former is required for the smaller vise.) Add enough to the cheek width to make it approximately 18″ above the bench surface when mounted.

What is a face vise and how do you use it?

A vise’s location on the bench determines what it’s called. Face vises are connected to the bench’s front; end vises are fastened to the end. If you can only afford one, get a face vise. Right-handers should install a face vise at the bench’s far left front edge and an end vise at the bench’s far right corner.

How do you attach vise jaws to a wood bench?

Attach the rear cheek with #10 flathead woodscrews after countersinking the holes in the jaw. Make a hardwood spacer block thick enough to locate the top of the vise jaws 1⁄2" below the top of the bench, measuring in the same manner as explained for a simple mounting. Trace the jaw’s outline and its screw holes onto the spacer.

Where should a bench vice be placed?

0:5211:36How to Install a Bench Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo I personally like it in the corner of your other workbench whenever possible and as close as youMoreSo I personally like it in the corner of your other workbench whenever possible and as close as you can get it to the edge on both sides here and equal.

What side of the bench should a vise go?

Bench vises hold better when you push toward them, with the mass of the bench behind the workpiece. That's why face vises usually are placed on the left end of the bench.

How do you install and mount a vise without drilling holes in your workbench?

3:0414:02How to mount a vise without drilling holes in your workbench - YouTubeYouTubeStart of suggested clipEnd of suggested clipOne of these transfer punch sets. And what what this will allow you to do is perfectly center centerMoreOne of these transfer punch sets. And what what this will allow you to do is perfectly center center up your your hole and leave a mark exactly dead center of your hole.

How do you install a vise screw?

6:109:11How to Mount a Workbench Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipBefore sliding the vise screw all the way into the base. You have to reinstall the two elements ofMoreBefore sliding the vise screw all the way into the base. You have to reinstall the two elements of the quick release assembly that make this vise so handy to use align those parts.

Should a workbench have an overhang?

For any workbenches between 7 and 10 feet long, you really can't go wrong with 12 or 15 inches of overhang on both sides. It gives you a wide-open workspace, plenty of room for clamps, it's about as stable as they come, and the symmetry gives it a very neat, classic look.

Does a workbench need to be level?

When you pile tools on your bench it's important to have it level so that they don't roll off. It's that simple. If your bench wobbles or slopes your expensive hand tools could go clattering to the floor and be damaged. It's equally important to have your workbench level when you are working at it.

How do you bolt down a bench vise?

0:075:05BENCH VISE - How To Install A Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipSide is close enough to an at the edge. Where if you have a long item that you're working on thatMoreSide is close enough to an at the edge. Where if you have a long item that you're working on that you need to clamp that it will clear. The side of the bench.

How do you mount a vise without drilling holes?

The DesignStep One: Begin by making a plate to mount the vise. ... Step Two: Cut two matching layers of plywood to the same size.Step Three: Cover one side of each piece with glue, then sandwich them together and clamp to allow the glue to dry.More items...

How do you attach a vice?

0:281:57How To Properly Mount A Vice To Any Surface.. - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's going to go right on top I already pre-drilled the holes. Bolts washer it's going to go rightMoreIt's going to go right on top I already pre-drilled the holes. Bolts washer it's going to go right through. Now. I'm going to drill holes on here to match here. And then what I'm going to do is once I

What clamping position should be considered when mounting a vise on a workbench?

What clamping position should be considered when mounting a vise on a workbench? The vise should be positioned so that a long piece can be held vertically in the jaws without interference from the workbench.

How do you install a leg vise?

3:357:00Installing a Leg Vise on a Workbench - 253 - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe nut on from the backside. And then secure the nut with a couple wood screws. The leg vise thatMoreThe nut on from the backside. And then secure the nut with a couple wood screws. The leg vise that we are installing is modeled after the leg vise that I use in my shop.

What are the parts of bench vice?

2.2.1 Bench vice It essentially consists of a cast steel body, a movable jaw, a fixed jaw, both made of cast steel, a handle, a square threaded screw and a nut all made of mild steel.

Where do you put face vise?

4:295:40Woodcraft 101:How to Install a Face Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI added 3/4 to both ends of the cheek plates. And I installed it in a flush manner. So that the backMoreI added 3/4 to both ends of the cheek plates. And I installed it in a flush manner. So that the back cheek. Here is flush with the front of my table that way.

Where do you position woodworking vise?

1:184:38How to install a Woodworking Vise// Woodworking// Quick Release ViseYouTubeStart of suggested clipEnd of suggested clipAll the holes for the mounting of the vise plate to the bottom side of the bench.MoreAll the holes for the mounting of the vise plate to the bottom side of the bench.

How do you mount a woodworking vise?

3:346:41Installing a Woodworking Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipTo attach the vise to the bench I used some 2-inch lag screws with washers. Those will hold it upMoreTo attach the vise to the bench I used some 2-inch lag screws with washers. Those will hold it up from the bottom inside these tabs I clamped the vise in place and used an awl to poke holes where the

Do I need a tail vise?

The main reason why a traditional tail vise is so darn useful is because of the unobstructed gap you get in the front of your bench. this gives you the perfect way to solidly clamp chair legs, or any long part that needs to be held while you work on it from one end.

Where is the vise on a bench?

A vise’s location on the bench determines what it’s called. Face vises are attached on the front, or face, of the bench; end vises are installed on the end. The best benches have both, but if you can only afford one, I’d go for a face vise initially.

Where should a right-hander mount a vise?

Right-handers should mount a face vise at the far left of the bench’s front edge and an end vise on the end of the bench at the foremost right-hand corner. Southpaws will want to do the opposite. When retrofitting an existing bench, make sure the vise mechanism won’t interfere with the bench legs. Shift the top if necessary to accommodate the vise.

How big of a vise should I use for face planing?

Because a face vise is used for general work as well as for planing edges, I recommend investing in a larger vise (at least 10"). Since it’s primarily used in tandem with bench dogs to secure boards for face-planing, a smaller end vise should suffice.

How to attach a vise to a spacer block?

Use a straightedge to ensure the face of the jaw is flush with the edge of the ben ch. If it’s proud, level it with a hand plane.

How to measure spacer block thickness?

To determine the thickness of your spacer blocks, place the rear jaw upside down on the inverted benchtop and measure how much the top of the jaw projects beyond the underside. Add to that 1⁄4" for a 7" vise, or 1⁄2" for a 10" vise. (The former is necessary for better dog height on the smaller vise.)

How to make a cheek on a bench?

Make the front cheek, and attach it with washers and roundhead woodscrews, reassemble the vise, and turn the benchtop over. Hand-plane the cheeks flush with the benchtop (Photo H). My bench had radiused edges, so I chiseled away the sharp point at the corner of the cheek. Finally, apply a couple of coats of wipe-on finish to all raw wood surfaces.

How big is a face vise?

Because a face vise is used for general work as well as for planing edges, I recommend investing in a larger vise (at least 10"). Since it’s primarily used in tandem with bench dogs to secure boards for face-planing, a smaller end vise should suffice. I prefer a small (7") model, because its dog is only 31⁄2" from the front edge of the bench, which is convenient for clamping workpieces for face-planing and other operations.

What size vise should I use for a bench dog?

Because a face vise is utilized for both general work and edge planing, I suggest a bigger vise (at least 10″). A smaller end vise should work well with bench dogs to secure boards for face-planing. For face-planing and other tasks, I use a tiny (7″) model since the dog is only 312″ from the front edge of the bench.

What is a workbench without vises?

Let’s face it: a workbench without vises is really nothing more than an assembly table. Vises offer the strength required to secure workpieces during planing, sawing, routing, and other tooling operations. The venerable Record vise is one of the many commercial types that has withstood the test of time because it is simple to install, simple to use, and built to last generations.

How to attach a vise to a spacer block?

Place the vise on the spacer block, cheek in notch. Mark and drill pilot holes, then lag bolt the vise in place. Using a straightedge, align the jaw with the bench’s edge. If it’s prideful, plane it.

How to cut a notch in a bench?

Backsaw the crosscut into the benchtop edge. Then use a circular saw to cut the notch with a straightedge clamped to the bench. Then rip the notch until it intersects the previous crosscut.

How to make a wooden cheek?

First, measure the thickness of the jaw to create the wooden cheek. Using a 1 inch thick hardwood board “Plane it to the jaw’s thickness if it’s broader. In order to make the rear jaw, align the bottom borders as indicated in Figure 1 “at either end To create the U-shaped cheek filler, crosscut and bandsaw the piece. Glue it on 34 “-similar size thick stock, as indicated.

How far does the rear jaw extend on a 7" vise?

Place the rear jaw upside down on the inverted benchtop and measure how far the top of the jaw extends below the bottom. 14″ for a 7″ vise, 12″ for a 10″ vice (The former is required for the smaller vise.)

How big of a hole do you drill for a dog vise?

Most commercial dogs fit 34-mm holes bored perpendicular to the tabletop. Make a drill guide block from 2″ thick material by drilling a 34″ diameter hole in the middle.

Start your 14-day FREE trial to watch this video

Matt and Mike didn’t skimp on any aspects of this workbench, but particularly not on the benchtop and vise. In this episode, they discuss how they assembled the 3-in. maple benchtop and installed the Lie-Nielsen twin-screw vise.

How to Build the Ultimate Shaker Workbench

In this first episode of the video workshop, Mike Pekovich and Matt Kenney explain how the bench is constructed.

In Search of the Perfect Workbench

A trip to the Hancock Shaker Village provides some fascinating background on Shaker machinery and workbenches.

Prepping the Base for Glue-Up

Apply milk paint to the panels, fashion some drawbore pegs, and you're ready to glue up the base of the bench.

How to Install the Benchtop and Vise

Learn how to glue up the 3-in. maple top and install a twin-screw vise.

How to Install a Sliding Deadman on a Workbench

Install this versatile jig to support your workpieces, apply a finish coat of Danish oil, and your bench is complete.

How long does it take to attach a bench dog to a bench?

This might be useful in the future if I'm cutting something quite long and need the side-to-side clearance and support in the middle. This took about 6 seconds.

What to do if you don't have a table saw?

If you don't have a table saw, you can do this with a circular saw or even a handsaw. Just make sure to mark a baseline, and keep everything secure.

Can you reinforce dado joints?

Allow the glue to cure. You could reinforce this dado joint with screws or dowels if you want, but with this much contact and the dimensional strength of the plywood, I think it'll stand up to any force I can apply with my hands. Also, at this point, I wiped on a coat of Danish Oil.