Install the vise with washers and lag screws that project through clearance holes in the two spacer blocks. Simple mounting The easiest installation entails making spacer blocks to set the tops of the metal jaws below the bench surface while screwing the vise to the underside of a bench.

Full Answer

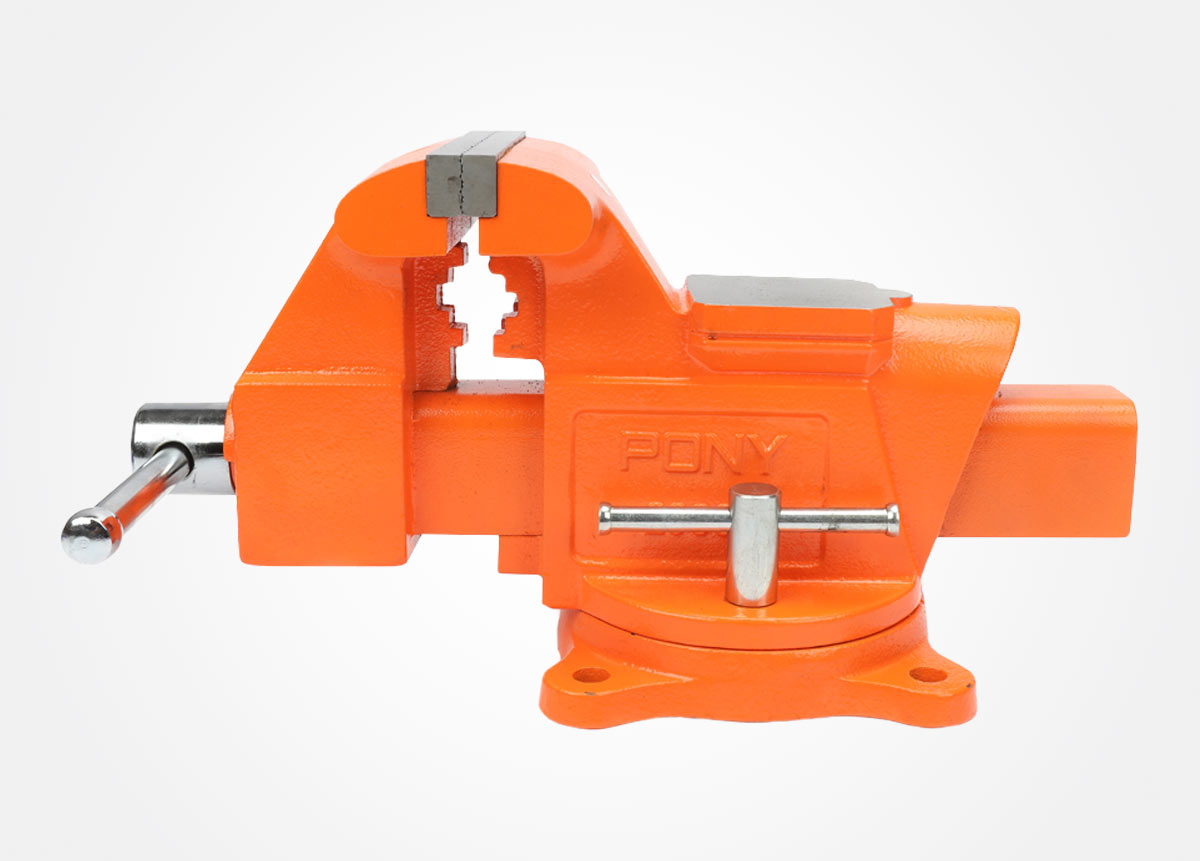

What is the Pony woodworker's vise?

The Pony Woodworker's Vise is for medium duty home, shop or professional use. It is designed to mount to the face of wood work benches. The top edges of the jaws are typically brought flush with the bench top.

How do you install a cast iron vise?

If you are installing a bench top vise, place the vise in position and mark where the holes will be. Drill the holes right through the bench top and bolt the vise into the top. To install an edge cast-iron vise, remove the front jaw, screw and side bars to make the vise lighter and easier to work with.

How do you attach vise jaws to a wood bench?

Attach the rear cheek with #10 flathead woodscrews after countersinking the holes in the jaw. Make a hardwood spacer block thick enough to locate the top of the vise jaws 1⁄2" below the top of the bench, measuring in the same manner as explained for a simple mounting. Trace the jaw’s outline and its screw holes onto the spacer.

How do you mount a dog vise to a bench?

You need to position it well below the bench top or the dog will stick above the work surface. You are likely to need a filler block between the bench underside and the mounting bracket portion of the vise to to produce the intended spacing. Install the filler block for the vise.

How do you mount pony vise?

3:346:41Installing a Woodworking Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipThose will hold it up from the bottom inside these tabs I clamped the vise in place and used an awlMoreThose will hold it up from the bottom inside these tabs I clamped the vise in place and used an awl to poke holes where the screws will. Go.

How do I attach a woodworking vise?

2:274:38How to install a Woodworking Vise// Woodworking// Quick Release ViseYouTubeStart of suggested clipEnd of suggested clipThen install the screws that will mount the front of the vise to the front jaw take quick-releaseMoreThen install the screws that will mount the front of the vise to the front jaw take quick-release vise you just barely want to put the screws in the guide rods in place so that you can situate.

How do I install a workbench vise?

1:0910:36Mounting a Workbench Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI'm going to start mounting. The end vise on the bench top by first removing the nuts that hold theMoreI'm going to start mounting. The end vise on the bench top by first removing the nuts that hold the end assembly to the guide rods. Go ahead and slip that out. And set it aside.

How do I attach a vise to a table?

0:075:05BENCH VISE - How To Install A Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipSide is close enough to an at the edge. Where if you have a long item that you're working on thatMoreSide is close enough to an at the edge. Where if you have a long item that you're working on that you need to clamp that it will clear. The side of the bench.

Where do you mount a vise to a workbench?

0:5211:36How to Install a Bench Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo I personally like it in the corner of your other workbench whenever possible and as close as youMoreSo I personally like it in the corner of your other workbench whenever possible and as close as you can get it to the edge on both sides here and equal.

How do you hang a vise without a bench?

2:096:17Mounting a vise without taking up bench space. - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo you just go to the spot that it's at. And the holes are just a little bit loose so that they don'MoreSo you just go to the spot that it's at. And the holes are just a little bit loose so that they don't bind up.

How do you fix a vice to a workbench?

0:252:11How to Fix a Vice on a Workbench | Woodworking - YouTubeYouTubeStart of suggested clipEnd of suggested clipMake sure the handle is jutting out that you can loosen and tighten the vise easily mark the spotMoreMake sure the handle is jutting out that you can loosen and tighten the vise easily mark the spot where you will drill a hole using a pencil. Use a center punch to make the pilot holes.

What clamping position should be considered when mounting a vise on a workbench?

What clamping position should be considered when mounting a vise on a workbench? The vise should be positioned so that a long piece can be held vertically in the jaws without interference from the workbench.

How does a quick release wood vise work?

0:401:54Introducing the Veritas Quick-Release and Inset Vises - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt features an extruded aluminum screw cover which keeps debris away from the screw mechanism andMoreIt features an extruded aluminum screw cover which keeps debris away from the screw mechanism and prevents the workpiece from touching the lubricated main screw.

How do you attach a wood vice to a bench?

2:5922:26How to fit a Woodworking Vice - YouTubeYouTubeStart of suggested clipEnd of suggested clipAs I go through I've put a clamp here and here and I've measured the distance from the edge of theMoreAs I go through I've put a clamp here and here and I've measured the distance from the edge of the cutter. To this edge of the fence. And the same at the back.

How does a quick release wood vise work?

0:401:54Introducing the Veritas Quick-Release and Inset Vises - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt features an extruded aluminum screw cover which keeps debris away from the screw mechanism andMoreIt features an extruded aluminum screw cover which keeps debris away from the screw mechanism and prevents the workpiece from touching the lubricated main screw.

Crosscut Sled for Large Panels

Steve Fikar's panel sled is guided by a single runner in one miter slot attached to a torsion-box base to keep the sled light.

Shop Talk Live Podcast

Our biweekly podcast allows editors, authors, and special guests to answer your woodworking questions and connect with the online woodworking community.

Can you take a vise off?

Now that you have your measurement and the jaw (s) cut, you can take the vise off.

Can you add an outer jaw to a vise?

So on my vise i chose to only add an outer jaw, and use the edge of the benchtop for my inner jaw but you can do this a couple different ways so do what works best for you! Cut the oversized jaw to length and width, but dont forget to leave a little extra so you can dial it in later.

Can you remove the quick release nut?

Remove quick release nut, but REMEMBER how it goes, i suggest taking a picture of it's oreintation so that you make sure it goes back correctly, if not the vise will not operate as intended.

How far above jaws does a dog go in a vise?

On some vises the dog extends up to ½ inch above the jaws. You need to position it well below the bench top or the dog will stick above the work surface. You are likely to need a filler block between the bench underside and the mounting bracket portion of the vise to to produce the intended spacing.

Where should a vise be on a bench?

The vise should be in a place where it is easy to use, but not where you will catch your clothes on it or where it will be a nuisance. Right handers will usually prefer the vice to be on the left hand of the bench, left handers, on the right.

How big of a vise should I use for face planing?

Because a face vise is used for general work as well as for planing edges, I recommend investing in a larger vise (at least 10"). Since it’s primarily used in tandem with bench dogs to secure boards for face-planing, a smaller end vise should suffice.

How to attach a vise to a spacer block?

Use a straightedge to ensure the face of the jaw is flush with the edge of the ben ch. If it’s proud, level it with a hand plane.

How to measure spacer block thickness?

To determine the thickness of your spacer blocks, place the rear jaw upside down on the inverted benchtop and measure how much the top of the jaw projects beyond the underside. Add to that 1⁄4" for a 7" vise, or 1⁄2" for a 10" vise. (The former is necessary for better dog height on the smaller vise.)

How to make a cheek on a bench?

Make the front cheek, and attach it with washers and roundhead woodscrews, reassemble the vise, and turn the benchtop over. Hand-plane the cheeks flush with the benchtop (Photo H). My bench had radiused edges, so I chiseled away the sharp point at the corner of the cheek. Finally, apply a couple of coats of wipe-on finish to all raw wood surfaces.

How big is a face vise?

Because a face vise is used for general work as well as for planing edges, I recommend investing in a larger vise (at least 10"). Since it’s primarily used in tandem with bench dogs to secure boards for face-planing, a smaller end vise should suffice. I prefer a small (7") model, because its dog is only 31⁄2" from the front edge of the bench, which is convenient for clamping workpieces for face-planing and other operations.

How to cut a notch in a bench?

Make the crosscut into the benchtop edge with a backsaw. Then clamp a straightedge to the bench to guide a circular saw to cut the length of the notch. Rip the notch until you intersect the previous crosscut (Photo C), and then finish up with a handsaw.

What is a workbench without vises?

Let’s face it; a workbench without vises is basically just an assembly table. Vises provide the muscle for securing workpieces for planing, sawing, routing, and other tooling operations. Of the myriad commercial models, the venerable Record vise is one that has stood the test of time, because it’s simple to install, easy to operate, and designed to survive generations of use. Although it’s no longer in production, several clones are available, including the Eclipse vise, which I show in this article. Similar vises may differ in features, but attachment is similar.

Have a question?

There was a problem completing your request. Please try your search again later.

Product Description

The Pony Woodworker's Vise is for medium duty home, shop or professional use. It is designed to mount to the face of wood work benches. The top edges of the jaws are typically brought flush with the bench top.