- First thing you'll want to do is cut your base material to size - a little oversized actually. ...

- Next, cut your "surface" material to the same size as the base - it doesn't have to be exact because once it's bonded to the base, you'll clean up the ...

- Using contact adhesive, bond the surface material to the base. ...

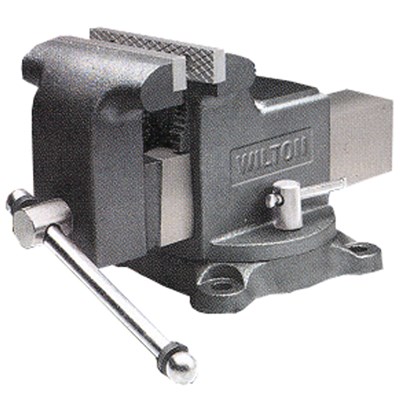

What is a bench vise and how to use it?

In order to work with metal and wood safely, a bench vise is an essential tool for your workbench. These units offer powerful grip and stability to make your work easier and quicker. At Gearhungry, we have created a list of our favorite picks to help you make the best decision when searching for the best bench vise.

How do you install a vise without a front vise?

To install without a front vise, just use two small but heavy-duty clamps on either side, making sure to butt the vertical piece right against the edge of your bench. This approach secures the vise in under ten seconds.

What is the best vise for metalworking?

The Tekton vise features a 120-degree rotation swivel base, with a dual-lock to keep everything in place. You don’t need an additional work surface with such a unit in your garage, as it also comes with a polished anvil for the forming and shaping of your metal pieces.

What is the best vise to use with dumbbells?

The second was a Moxon-style vise from Rex Bostrom that ingeniously used dumbbells as the screw hardware . The best part is that neither vise requires a workbench to build or use. I did all of the work on our tablesaw outfeed table, which was the closest analog I could find to a dining room table. My take on Steve Farnow’s dovetailing box.

How do I temporarily mount a vise?

0:001:03Portable Vise Mount - YouTubeYouTubeStart of suggested clipEnd of suggested clipI have a little lip around the board keeps it flush to the match. And you can mount this on anyMoreI have a little lip around the board keeps it flush to the match. And you can mount this on any bench you can mount in any height. And it's a good way to keep the vise.

How do you hang a vise without a bench?

2:096:17Mounting a vise without taking up bench space. - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo you just go to the spot that it's at. And the holes are just a little bit loose so that they don'MoreSo you just go to the spot that it's at. And the holes are just a little bit loose so that they don't bind up.

Can you attach a vise to a portable workbench?

2:296:53How To Attach A Bench Vise to your Workmate 425 - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou may want to use wing nuts on both sides as I've done here. If you believe you'll be swivelingMoreYou may want to use wing nuts on both sides as I've done here. If you believe you'll be swiveling your vise in place you'll need to use shorter bolts than I have in this example.

What do you attach vise to?

0:5211:36How to Install a Bench Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipYour your vise here you want it as closest to the edge as possible. And the reason for that is thisMoreYour your vise here you want it as closest to the edge as possible. And the reason for that is this back jaw right here this back sha has to be in front of your workbench.

How do you secure a vise without drilling?

The DesignStep One: Begin by making a plate to mount the vise. ... Step Two: Cut two matching layers of plywood to the same size.Step Three: Cover one side of each piece with glue, then sandwich them together and clamp to allow the glue to dry.More items...

How do I attach a vise to a table?

0:075:05BENCH VISE - How To Install A Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipSide is close enough to an at the edge. Where if you have a long item that you're working on thatMoreSide is close enough to an at the edge. Where if you have a long item that you're working on that you need to clamp that it will clear. The side of the bench.

Where is the best place to put a vise on a workbench?

That's why face vises usually are placed on the left end of the bench. When sawing workpieces (below), a left-side vise also lets you hold onto the offcut, with the keeper piece safely secured in the jaws, resulting in a cleaner cut. But that said, you can mount a vise wherever it suits you best.

How do you put a vise on a tool box?

1:113:26How to mount a bench vise to a Husky tool box - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd I'm gonna go all the way through the wood to the top toolbox. And then I'll just mount it onMoreAnd I'm gonna go all the way through the wood to the top toolbox. And then I'll just mount it on those three. Points. Can I just wallow death the holes a tiny bit just make them a little bit.

What can I use if I dont have a vice?

2:053:05You Don't Have a Vice? - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo if you haven't got a bench vise or anything like that the hold you stock down or hold it firm sayMoreSo if you haven't got a bench vise or anything like that the hold you stock down or hold it firm say you're working on it this would be your next best bet I reckon the mask craft bench lock.

How do you make a removable vise?

0:082:15Removable vise mount | prototype woodworking - YouTubeYouTubeStart of suggested clipEnd of suggested clipWith those pieces laminated. Together i'm going to go ahead and square it off i want to keep itMoreWith those pieces laminated. Together i'm going to go ahead and square it off i want to keep it about an inch away from where the vise would be mounted. And due to the odd shape some of my corners.

How do you attach a bench vice?

3:346:41Installing a Woodworking Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI clamped the vise back in place and used an impact driver with a socket to drive the lag screws. InMoreI clamped the vise back in place and used an impact driver with a socket to drive the lag screws. In. The vise also gets secured on the front face through the jaw.

How do you make a bench stand vise?

0:3612:55Building a Simple & Cheap Vise Stand - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can do this really cheap really simple. The basic materials that we're going to use for our viseMoreYou can do this really cheap really simple. The basic materials that we're going to use for our vise Stan. There's going to be one two by four and two two by eight all eight feet long.

How do you put a vise on a tool box?

1:113:26How to mount a bench vise to a Husky tool box - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd I'm gonna go all the way through the wood to the top toolbox. And then I'll just mount it onMoreAnd I'm gonna go all the way through the wood to the top toolbox. And then I'll just mount it on those three. Points. Can I just wallow death the holes a tiny bit just make them a little bit.

How do you mount a woodworker vise?

3:396:41Installing a Woodworking Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI clamped the vise back in place and used an impact driver with a socket to drive the lag screws. InMoreI clamped the vise back in place and used an impact driver with a socket to drive the lag screws. In. The vise also gets secured on the front face through the jaw.

Where is the best place to put a vise on a workbench?

That's why face vises usually are placed on the left end of the bench. When sawing workpieces (below), a left-side vise also lets you hold onto the offcut, with the keeper piece safely secured in the jaws, resulting in a cleaner cut. But that said, you can mount a vise wherever it suits you best.

How do you make a bench stand vise?

0:3612:55Building a Simple & Cheap Vise Stand - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can do this really cheap really simple. The basic materials that we're going to use for our viseMoreYou can do this really cheap really simple. The basic materials that we're going to use for our vise Stan. There's going to be one two by four and two two by eight all eight feet long.

How to mount a vise on a bench?

Center your vise on the base. Keep in mind that you want the back jaw of the vise to clear the outer edge of the vise - so that you can have long work pieces hang over the edge of the bench. When you have the vise positioned, mark your mounting holes.

How to make a table saw base?

First thing you'll want to do is cut your base material to size - a little oversized actually. Add about 1/8" to your base dimensions. Next, cut your "surface" material to the same size as the base - it doesn 't have to be exact because once it's bonded to the base, you'll clean up the edges on the table saw.

Step 2: Make the Legs

The base shape of the legs is a large "A" (or "R"). it is relatively easy to build from straight pieces.

Step 3: Build the Stretchers

The stretchers provide rigidity, they prevent the frame from racking and the bench from rocking. They are meant for easy disassembly.

Step 4: Assemble the Top to the Base

connect the top to the legs using bolts similar to the stretchers. I use 4 bolts - 2 on each side.

Step 5: Build the Leg Vise (moxon Style)

this leg vise is based on the Moxon style bench vise, check the video to see how it works, and see the assembly video above for a breakdown of the parts.

Step 7: Enjoy Your New Workbench!

I also added a bottom drawer (on wheels). it adds storage and also prevents stuff from rolling under the workbench :)

What is a Tekton 4 inch bench vise?

The Tekton 4-inch swivel bench Vise is an all-purpose, medium-duty unit that is well suited for the repair of vehicles, assembling of parts as well as all your metalworks. It is a safer unit as compared to the competition, and is engineered to help you work faster and better, knowing that your workpiece is securely in place. The level of confidence you receive from using this unit cannot be experienced with any other brand or model. It is the best bench vise around, and an essential unit your shop or garage cannot function without.

What is a Yost LV-4?

The Yost LV-4 Home Vise is one of the many products that tell the centenary story of the Yost company. With over a hundred years in the production business, Yost is well-known for creating some of the world’s best tools. All items created are launched only after rigorous testing and evaluation, to ensure that they offer nothing but the best of performance to users. Yost prides itself in the creation of quality clamping tools, a passion they have fuelled and perfected over the years. Whenever you decide to purchase a new bench vice for sale, think about the Yost LV-4 Bench Vise before any other model.

What makes a bench vise sand faster?

Sanding: bench vises make the process of sanding quicker by offering stability in times where the pressure is needed.

Why do we use pivots?

Pivots are used to offer users with better access to the objects being worked on, making the process of cutting and sanding easier. Anvil - an anvil is a flat surface added to the bench vise to enable you to work with ease. It is a durable surface that helps users whose jobs involve regular striking of a material.

What is an anvil in a bench?

Anvils protect your tools, materials and workbench from experiencing extreme damage associated with your works. Mount Type - If you're planning to use significant clamping pressure, the mount is an essential feature needed in your bench vise. It is a heavy-duty way of fixing your unit.

What is MV8 vise?

The Performance Tool MV8 Hammer Machinist Vise is a heavy-duty, well-engineered bench vise, made specifically for heavy-duty works. It is a durable unit with increased longevity, made possible through its chrome plated hardware and durable powder coat finish. At first glance, this workbench unit may seem intimidating, but it is one of the best groups in the industry, recommended for both DIY beginners and professionals who want to amen larger items. The heavy-duty nature of this unit makes it highly resistant to wear and tear from regular use.

What are the features of a bench vise?

There are some bench vises with unique features that set them apart from the competition. Some features to note when making a selection include the anvil, swivel and quick release, but the most critical element is the jaw of your bench vise.

Product Recommendations

We don't have any links to project supplies and hardware for this particular project yet, but here are some other products that might be of interest to you. (We may receive commission when you use our affiliate links. However, this does not impact our recommendations.)

Universal Fence Clamps

The United States Customary System of Units (USCS or USC), more commonly referred to as the English or Imperial system, is the standard set of units for our plans. It uses inches and feet for measurement. This is the one you probably want if you are in the United States, and it is the one we have traditionally offered on this website.

Can you reinforce dado joints?

Allow the glue to cure. You could reinforce this dado joint with screws or dowels if you want, but with this much contact and the dimensional strength of the plywood, I think it'll stand up to any force I can apply with my hands. Also, at this point, I wiped on a coat of Danish Oil.

How long does it take to attach a bench dog to a bench?

This might be useful in the future if I'm cutting something quite long and need the side-to-side clearance and support in the middle. This took about 6 seconds.

What to do if you don't have a table saw?

If you don't have a table saw, you can do this with a circular saw or even a handsaw. Just make sure to mark a baseline, and keep everything secure.

Do I need to clean my Douglas fir blade?

Yes, I know I need to clean my blade. I've been cutting a lot of relatively fresh Douglas fir for a project, and the pitch has left a lot of build-up. I'll be following this tutorial soon!