How To Make A Wooden Drill Press Vice

- Material used : 12mm Bolt with nut ( 7’’ length ) ...

- Step 1 :- Cutting parts I have used 12mm plywood in base plate so first of all cut the plywood of 8’’ length and 2.25” width of 2 pieces. ...

- Step 2 :- Assembly of parts ...

- Step 3 :- Vice bolt and handle ...

- Step 3 :- Vice bolt and handle ...

What is the best drill press for woodworking?

Top 7 Drill Presses for Woodworking Review 2022

- Editor’s Choice Jet JDP-17. If you are in the market for the best drill press for woodworking, then you need to check out this model from Jet.

- Best Floor Drill Press NOVA 58000 Voyager DVR Drill Press. The great thing about drill presses is that they can be used for a variety of materials. ...

- Best Benchtop Drill Press WEN 4214. ...

How to attach a vise to a drill press?

How to attach a Vise to a Drill Press

- Place the drill vice press atop the table of the drill press.

- Align the holes on the drill press vise with holes on the drill press table.

- Slide a 3/8 washer over 3/8 inch bolt and gently inch this through the hole aligned on the drill press table.

- Rotate the drill press vise to align another hole with the drill press table. ...

How to use a drill press vice?

Using the drill press vise

- Mark the drill point. Get the object you are working on and mark where you want to drill.

- Open the jaws. After making a mark, open the jaws of the drill press vise by turning the handle in an anti-clockwise direction.

- Position the workpiece. ...

- Close the jaws. ...

- Align the drill bit. ...

- Drill. ...

How to choose drill press?

How to Choose a Good Drill Press – Some other points to consider

- Power of the drill press. With power levels being calculated in terms of horsepower, it’s pretty apparent that you’d want to have a model that’s powerful enough to ensure ...

- Speed levels. Not every hole can be drilled with the same speed and power, exactly. ...

- Multipurpose nature. ...

How do you build a drill press vice?

3:539:44Homemade Drill Press Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI cut the pins which are just wooden dowels down to their final size and tested the fit of theMoreI cut the pins which are just wooden dowels down to their final size and tested the fit of the backing on the base. After that I started laying out the rest of the components.

How do you make a drill press clamp?

0:011:16Make Your Own Drill Press Hold-Down! (Free Plans) - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut a good solution is just to make your own you can do that with a scrap piece of wood. You justMoreBut a good solution is just to make your own you can do that with a scrap piece of wood. You just drill an a slotted hole at the top. And then you can cut out the shape here on the scrap at the band.

How do you make a wooden vise?

0:167:17How to make a Workbench Vise ( DIY MOXON VISE ) - YouTubeYouTubeStart of suggested clipEnd of suggested clipOn one side of the jaw. I need to round out a dado slab. This will need to be equal to the thicknessMoreOn one side of the jaw. I need to round out a dado slab. This will need to be equal to the thickness of the plywood that will be used for the base the prow what I'm using is a bit thinner than 3/4.

How do you make a wooden drill press?

0:006:25Making A Portable Drill Press / Drilling Guide - YouTubeYouTubeStart of suggested clipEnd of suggested clipAround i'm going to start with that nose piece cut it out on a table saw and then drill the closestMoreAround i'm going to start with that nose piece cut it out on a table saw and then drill the closest size hole that i have in a forstner. Bit and then i can use my spindle sander to widen out the hole.

How do you make a drill press table?

0:263:35Building the Ultimate Woodworking Drill Press Table - Part 1 - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's a double layer of three-quarter inch baltic birch. And it's nice and wide i've also added someMoreIt's a double layer of three-quarter inch baltic birch. And it's nice and wide i've also added some laminate on top it's it's not necessary. But it's going to make the top last a long time.

Why is it necessary to use clamps when drilling a drill press?

Use a clamp or drill vise to prevent work from spinning. Make sure the drill bit or cutting tool is locked securely in the chuck. Remove the chuck key before starting the drill press.

What kind of wood do you use in a wood vise?

You can use plywood, a good grade, or solid wood, even pine, if that's what you have, to line the jaws of your vise. In this case I've chosen sapele, an african hardwood with perfect hardness and compression for this work. I've used it before and it's one of the best.

How do you make a wooden screw vise?

10:4013:26How to Make a Leg Vise With A Wooden Screw All Hand ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd give it a nice clean look and feel I put in one screw. Into each hole. So there are two screwsMoreAnd give it a nice clean look and feel I put in one screw. Into each hole. So there are two screws in each plate. And can then go around the main screw of the vise.

What can I use instead of a vise?

Cut out this bird's mouth shape using whatever you have: a back saw, jig saw, coping saw, band saw. Set up the long piece of wood as a stop against the end your worksurface. If you're right handed, that's the left side; if you're a leftie, then the right side. Clamp or screw it in place.

Can you turn a hand drill into a drill press?

For about $25 you can buy an accessory that will turn your hand drill into a portable drill press. Just take your drill bit out of your hand drill and attach your hand drill to the portable drill press. Then just go ahead and drill. A perfectly straight hole every time!

How do you make a drill press jig?

3:0211:00DIY Drill Press Jig | Homemade Woodworking - YouTubeYouTubeStart of suggested clipEnd of suggested clipPress into a jigsaw of sorts. So technically kind of stepping out of the bounds here but you couldMorePress into a jigsaw of sorts. So technically kind of stepping out of the bounds here but you could actually use the drill press to make circular cutouts.

Do I need a drill press vise?

If you want to avoid accidents when drilling through material such as wood, metal, or plastic, then you need a proper drill press vise to hold the items securely in place and avoid accidental injuries. Keep your drill from slipping.

What is a hold down clamp?

A hold-down clamp is one of the most important pieces of equipment in any workshop, as it allows you to manage the workpiece. Its purpose is straightforward: to keep objects in place while you execute another action on them.

How do you use a hold down clamp?

1:553:41Leigh Bench & Surface Hold Down Clamps - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply drill a mounting hole at the desired location. Then attach one of the included surface clampMoreSimply drill a mounting hole at the desired location. Then attach one of the included surface clamp anchors either from below with the included mounting screws.

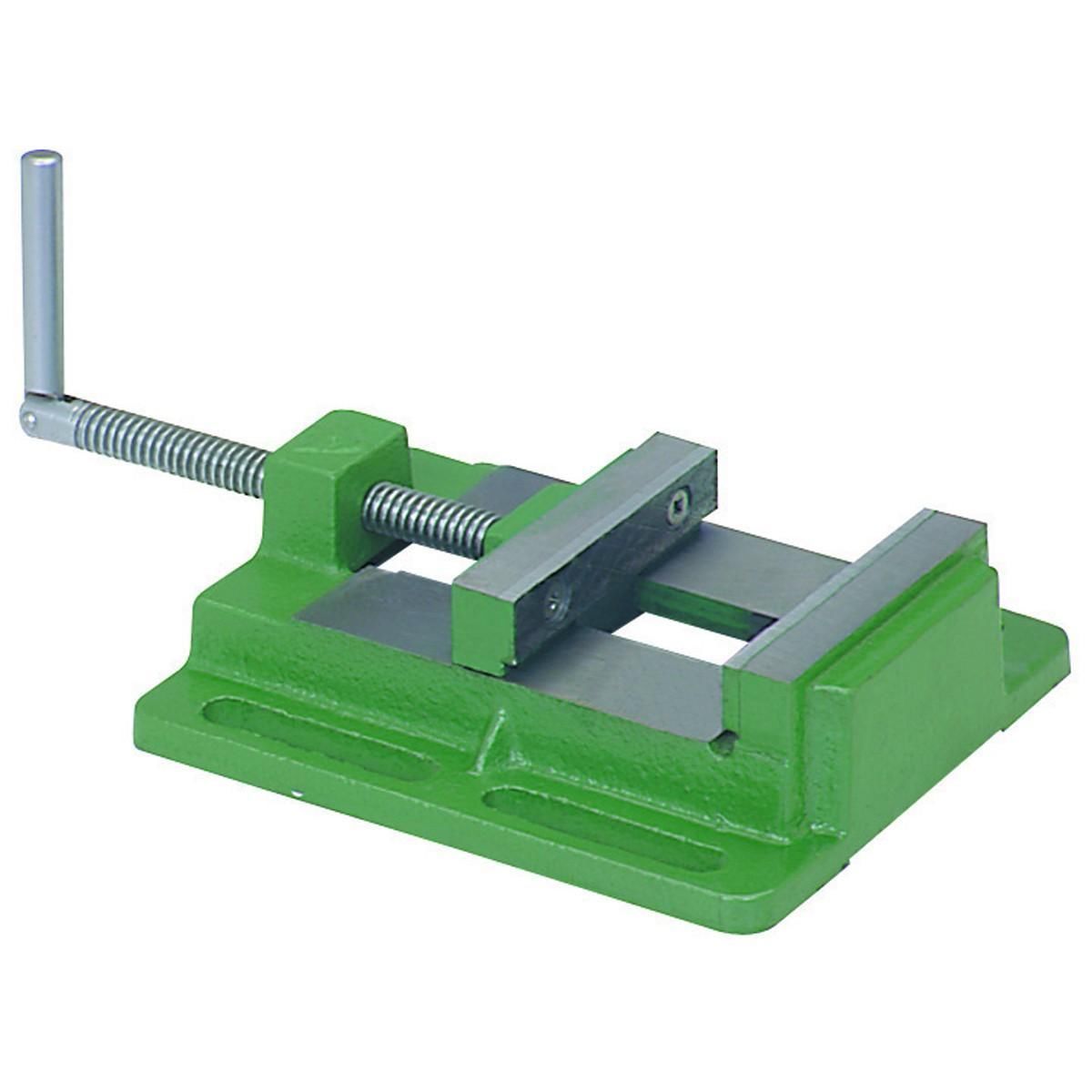

What is a drill press vice?

A drill press vice is a clamping device that is designed to be used in conjunction with a drill press. The vice is suited to being used with drill press due to its flat surface design. Drill press vice has a mounting holes which coincide with the mounting holes on the machine’s table. These holes allow bolts to be passed through in order to clamp the vice in place of table. The vice is mounted to the table of a drill press, and hold workpiece securely. It is used to clamp and position the workpiece during drilling operation.

What is a wooden vice?

This wooden vice is simple, easy and quick to make. Its capacity of about 4” and is used with drill press and also on work bench. It can be used to hold variety of materials, including metal, plastic and wood. It can also be used for industrial work, as well as by home hobbyists and craftsman.

Can I cut spruce wood for filler?

I missed a filler and just cut a piece of spruce and slipped it in. Not an overly critical area, so the softwood will work fine.

Can you slide back and forth on plywood?

Making all of the parts that slide back and forth to guide the moving jaw from plywood will solve the binding problem, and also simplify the construction. On the original, the “ways” were seperate strips of solid hardwood fastened on top of the plywood base, and the new design gets rid of those altogether.

Step 2: Main Piece

For this project I set myself to use mostly recycled materials and I think I got it at 90%!!

Step 3: Cutting the Main Piece

Once all the pieces marked, I cut them with the help of my beloved japanese saw, turning out 3 perfectly squared pieces.

Step 4: Joining the 3 Pieces

I used 2 rods of beech wood (230mm x 18mm) to join the 3 pieces created. Firstly, I drilled the central piece with a forstner bit of 18mm and once that piece is perforated, I used it as a template to match the holes exactly with the other 2 pieces.

Step 5: Inserting the Nuts in the Wood

As you can see in the photographs, I marked the center of the piece and then drilled it with a bit of 10mm (Thickness of the metal threaded rod). As previously, I used the hole of this piece to mark the one of the next piece.

Step 6: Locking System

The system used for the movement of the central piece forward (tighten) and backward (loosen) is very simple. I used 2 nylock nuts, one in front and one behind the piece, and also 2 washers at both ends.

Step 7: Base of the Vise

Once the main part of the vise assembled, I looked for a strong and resistant wood to screw it, I used Elondo wood and then to protect the wood I used wax.

Step 8: Screwing and the Vise Jaw

For a better resistance, I joined the parts with screws. I decided not to used glue for possible future adjustments.