DIY Woodworking Vise

- Welding a Nut to a Base. I want to use a M16 threaded rod for the linear movement. ...

- Welding a T-Piece, a Washer and the Rod. I want to use a T-piece pipe to hold the threaded rod and a wooden rod later. ...

- First Test Run. Both parts are finished. Let's try if everything fits together. Looks very good. The difficult part is done.

- The Moveable Jaw. So what we need next is a moveable jaw for the vise. ...

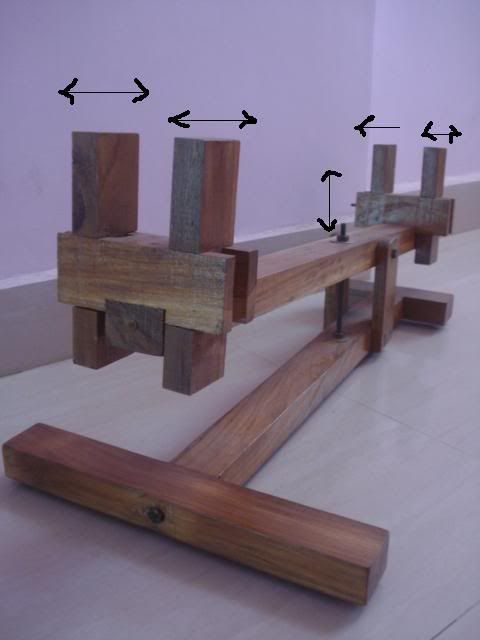

- Mounting the Rod and the Support Pipes to the Jaw. I use two 5/8" copper pipes to support the rod and to keep the jaw from rotating. ...

- Drilling the Holes to the Workbench Jaw. This time I need three holes which go right through the workbench. ...

- Building the Flange. Remember the washer, which we welded to the T-piece? Now you'll see its purpose. ...

- Mounting the Washer With the Nut to the Workbench. We are almost finished here. ...

- Building the Handle. The last step is to build a handle. I use a 2cm wooden rod made of beech. ...

- Done. Well that's it. Now I have my own workbench vise. ...

- Test Run. Ok now let's get to business. I did some minor projects with the vise. ...

Full Answer

How to use a DIY woodworking vise?

DIY Woodworking Vise Step 1: Welding a Nut to a Base. I want to use a M16 threaded rod for the linear movement. Therefore I need a nut or... Step 2: Welding a T-Piece, a Washer and the Rod. I want to use a T-piece pipe to hold the threaded rod and a wooden rod... Step 3: First Test Run. Both parts ...

How much do wood vise screws cost?

Wood Vise Screw - Standard Kit $ 229.00 Wood Vise Screw - Basic Kit $ 195.00 2X Wood Vise - Premium Kit $ 339.00 2X Wood Vise - Standard Kit $ 289.00 2X Wood Vise - Basic Kit

What kind of vise does Lake Erie Toolworks use?

Lake Erie Toolworks Wooden Vise Screw Kits Strong and secure workholding powered by a hard maple wooden vise for your workbench vise kit. Provides for all your woodworking vise and woodworking vice needs. Featuring an all premium USA made vise. Strong and secure workholding powered by a hard maple wooden vise for your workbench vise kit.

How to fix a broken vise rod?

To fix the rod, we added a small hole through the T-piece and the rod and insert a small bolt. Now you can turn the rod by turning the T-piece. The washer we added is very important. It will later hold the jaw of the vise and will make it move when you want to open the vise. Be careful by welding zinc-coated material! Acrid fumes can be developed!

How do you make a vice screw?

3:4213:03Making a Traditional Leg Vise With a Wooden Screw - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut slowly but truly you can drill a hole all the way through the leg. And leg chop. Once you get itMoreBut slowly but truly you can drill a hole all the way through the leg. And leg chop. Once you get it all the way through then you can do a little chamfering.

How do you make screw threads in wood?

3:3319:2677 - The Secret to Making PERFECT Wooden Threads - YouTubeYouTubeStart of suggested clipEnd of suggested clipAs the dowel is soaking you want to make sure that your tube is big enough for oil to get all theMoreAs the dowel is soaking you want to make sure that your tube is big enough for oil to get all the way around and you can see at this point my wooden dowel is actually floating on top of the oil.

How do I attach a vise to wood?

3:396:41Installing a Woodworking Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipThose will hold it up from the bottom inside these tabs I clamped the vise in place and used an awlMoreThose will hold it up from the bottom inside these tabs I clamped the vise in place and used an awl to poke holes where the screws will. Go.

How do you make a wooden screw by hand?

1:1813:22How To Make Wooden Screws - YouTubeYouTubeStart of suggested clipEnd of suggested clipNext up mineral oil soaking. And this to prevent the fibers of the wood from tearing. As you createMoreNext up mineral oil soaking. And this to prevent the fibers of the wood from tearing. As you create the threads and reusing this plastic container that some sealing tracks came packaged in.

How do you make wooden threads by hand?

0:488:43Make Wood Threads with this Amazing Router Jig! - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe pitch angle of our threaded rod. We can adjust the router up. And we can adjust this wholeMoreThe pitch angle of our threaded rod. We can adjust the router up. And we can adjust this whole carriage front cut back depending on the size of the project you might want to use in here.

How do you mount a carpenter's vice?

0:544:38How to install a Woodworking Vise// Woodworking// Quick Release ViseYouTubeStart of suggested clipEnd of suggested clipAs this will be very important later. Now you can use clamps to put the vise plate back in place useMoreAs this will be very important later. Now you can use clamps to put the vise plate back in place use a pencil to find the center of the holes. And then use a center punch to go ahead and mark them.

How does a wood vise work?

A wood face vise consists of a movable front jaw that is mounted to a broad, square beam that slides in and out of a matching channel. While the beam keeps the jaw steady and properly aligned, the jaw is driven by a wooden bench screw. The whole mechanism is fastened to the benchtop from below.

How do I make a quick release vise?

0:3017:20Homemade Quick Release Vice - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd I've just cut into lengths and I've cut them at 500 mil. So my next job is to cut three holesMoreAnd I've just cut into lengths and I've cut them at 500 mil. So my next job is to cut three holes one either side for my guide rails where I'm using this tubing here off an old trampoline.

How do you make screw threads?

0:161:33How to make a Thread Tap - Putting a tread into metal. - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo that it somewhat resembles an actual thread tap secure the bolt in a vise carefully cut the slotsMoreSo that it somewhat resembles an actual thread tap secure the bolt in a vise carefully cut the slots with a thin cutting disk your angle grinder cuts should look something like. This.

Can you tap threads in wood?

Since wood is really soft, you can likely "tap" the hole using just the bolt you want to put in it. Getting it threaded at the start can be a little tricky. Make sure you push the bolt into the hole while turning it so the threads catch.

What wood is best for threading?

Good threading can only be accomplished on woods that are dense, dry, stable and close grained. Most of the native woods we are accustomed to working with (Maple, Black Walnut, Cherry, Box Elder and others) are not suitable for thread chasing as they are too soft or too brittle.

How do you make wooden bolts?

0:238:07Making Wooden Nuts & Bolts - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut process is fairly similar you need to start off with square stock. So I've joined one side one.MoreBut process is fairly similar you need to start off with square stock. So I've joined one side one. Face. Then ripper to close dimensions. Then take it to the thickness. So to get very exact.

What are the jaws of a vise made of?

The jaws of the vise are made with stacks of individual blocks, glued together. Here, the blocks have been cut to rough size:

How many holes are there in a vise?

Four holes are drilled and these will be used to bolt the vise down to the bench.

What is the donut on a moving jaw?

The plywood donut beside it (photo above) is the keeper that goes on the lead screw inside the moving jaw. I used 1/2″ plywood for that, and it’s the only part that is not solid wood: The handle is a loose fit in the hole that goes through the head. Later, caps will be added to keep the handle from sliding out.

What bit is used for a slot in a sandbox?

The slot in the base is made using a 5/8″ bit and removing the material between the holes:

What is a test fit?

A test fit. The jaws should be matched at this point – same width, same height and meet evenly when pushed together.

Can you glue a vertical jaw?

When the glue dried, I sanded the jaw smooth and to final shape. Where the vertical jaw meets the horizontal is the only significant cross-grain glue joint. Given how narrow the parts are and how well seasoned the wood is, I don’t think this will be a problem. Using plywood would avoid this altogether.

Where are the off cuts from cutting the arc shape in the jaw parts glued?

Mostly for decorative purposes, the off cuts from cutting the arc shape in the jaw parts are glued to the side and base.

How to fix a rod on a nut?

To fix the rod, we added a small hole through the T-piece and the rod and insert a small bolt. Now you can turn the rod by turning the T-piece.

How long is a 5/8 copper rod?

I use two 5/8" copper pipes to support the rod and to keep the jaw from rotating. They have a length of 50cm. You can adjust the length to your needs.

Does a threaded rod work?

The threaded rod works fine, but the slope of the thread is very low. So you need a lot of turns to open the vise. Maybe I would use a higher slope next time. But this is just a convenience thing

Do you need clearance for horizontal movement?

Well you need some clearance for the horizontal movement due to the slop of the thread. When move the jaw you’ll see that it’s slightly misaligned to the other. But that clearance is very small and is easily achieved by the holes where the pipes go into. I used the copper pipes because they were scrap material from an old project and were laying around in my shop. I guess you could easily use different kind of pipes, hollow or solid, of different materials. Take what suites you is the cheapest.

Is maple wood good for a work bench?

very nice. The only problem I have is you should have used hardwoods for maximum durability. Some maple would not have been too costly. Over time you will find these things matter in a work bench. It really gets beat up and a soft wood will not endure as much abuse.

What is a good vise for a wooden thread?

A classic vise well suited to a wooden thread is the leg vise. If you don't have it, take a look at the "Workbench Book" by Scott Landis, it has a lot of information on vises and a section on making wooden threads for vises. It's a Taunton Press book, I think you can order it on another part of this web site. John W.

Why do you need to spread the load on wood threads?

3. The coarser the thread, the less contact area there is inside of the nut, wood threads are inherently weak, you need to spread the load as much as possible to keep the threads from shearing off.

What is the role of threaded rods in vises?

In a good vise design the threaded rod is only responsible for generating the clamping pressure, the alignment is supplied by some other components.

What book is about vises?

If you don't have it, take a look at the "Workbench Book" by Scott Landis, it has a lot of information on vises and a section on making wooden threads for vises. It's a Taunton Press book, I think you can order it on another part of this web site.

What is Roy Underhill's book called?

Roy Underhill has a book out called "The Woodwright's Workbook" University of north Carolina Press, 1986. The third chapter is "Screwboxes and Taps" which deals with very thing. Although I have done it, it looks do-able.

Does a shoulder vise drop?

We have a shoulder vise on a bench in our shop and it's jaw does drop a bit, it's the nature of the design. The drop doesn't seem to affect its use however.