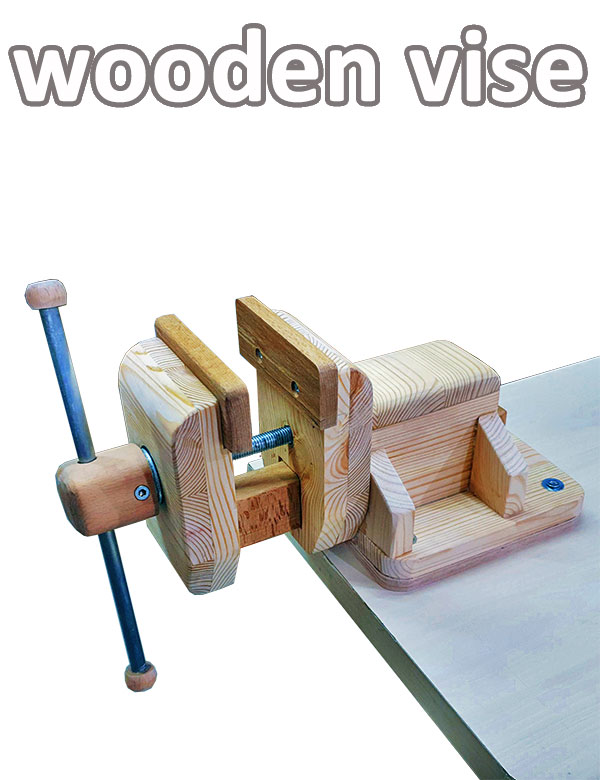

How to Make a Homemade Wood Vise

- Step 1. Use a tape measure to measure in three inches from each end of the 2-by-8-by-12-inch hardwood board.

- Step 2. Place the 2-by-4-by-12-inch hardwood board in front of you. Measure and mark three inches from each end of the...

- Step 3. Use a screw gun and three-inch deck screws to fasten the base of the vise to the back-bottom side of...

Full Answer

How to build a bowling ball vise?

“Fill the opened cavity almost to the top with lead shot to add weight, then seal the shot to the top of the hole with automotive Bondo® filler.” “Make a round cover for the flat top of the ball using metal, wood or Formica®. Mount your vise on top of this. Mine is a machinist’s vise using its mounting system.” “Make a base and you’re almost done.

How to make a wood vise?

Make a Bench Vise for Woodworking

- What You Need. About 16 linear feet of one by six hardwood (actual measurements ¾” x 5½”). ...

- Front Jaw. Cut two 32” long pieces from the one by six board. ...

- Rear Jaw. The rear jaw is L-shaped. ...

- Drill Holes for the Hex Bolts. Drill two ½” holes through the front jaw 3” from the short edge and 2 ¼” from the top edge. ...

- Make Handles. ...

- Use Your Bench Vise. ...

How to mount a woodworking vice?

Mounting a Wood Vise

- Select which Side. Choose which side of your workbench you will mount your work vise. ...

- Position the Wood Vice. Place the Wood Vice where you want it before bolting. ...

- Measuring. Mark out the holes where it requires bolting. ...

- Drilling. Then, drill the holes to allow the bolts to pass through your workbench. ...

- Bolting. ...

- Installing. ...

How to attach a vise to a drill press?

How to attach a Vise to a Drill Press

- Place the drill vice press atop the table of the drill press.

- Align the holes on the drill press vise with holes on the drill press table.

- Slide a 3/8 washer over 3/8 inch bolt and gently inch this through the hole aligned on the drill press table.

- Rotate the drill press vise to align another hole with the drill press table. ...

How do you make a homemade wooden vise?

0:207:17How to make a Workbench Vise ( DIY MOXON VISE ) - YouTubeYouTubeStart of suggested clipEnd of suggested clipOn one side of the jaw. I need to round out a dado slab. This will need to be equal to the thicknessMoreOn one side of the jaw. I need to round out a dado slab. This will need to be equal to the thickness of the plywood that will be used for the base the prow what I'm using is a bit thinner than 3/4.

What kind of wood do you use in a wood vise?

Generally, maple is used for wood vise jaws as it is durable enough to withstand the clamping force of a vise. However, softer woods such as pine can be used if your projects will be made from mostly soft hardwoods like cherry to prevent marring.

How thick should wood be for vise?

I would recommend at least one inch of hardwood onm the outside face of the chop. The inside face need not be as thick since it will not be compressed during tightening, so about 1/2" should do it.

How do you make a large wood vice?

0:306:39DIY Woodworking Bench Vise - Quick and Easy Shop Project - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo let's get. Started. Over at the table saw i cut a piece of 1 inch thick ash to 5 inches wide forMoreSo let's get. Started. Over at the table saw i cut a piece of 1 inch thick ash to 5 inches wide for the face of the vise.

How do you make wood vise jaws?

0:215:35Making New Vice Jaws - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's a hardwood. So it'll be nice and durable the jaws on my other vise they were just made fromMoreIt's a hardwood. So it'll be nice and durable the jaws on my other vise they were just made from some block board which is laminated pieces of pine with a veneer on both faces.

What wood should I use for a Moxon Vise?

2) When building the wood jaws for the moxon vise, which wood should I use? Walnut is my favorite species, but most of these I see are either southern yellow pine, cherry, or maple.

How do you make a wooden leg vice?

4:4112:03Making and Installing a Leg Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI cut a small piece of wood. And then used my scrap pieces of steel to weigh it. Down. After thatMoreI cut a small piece of wood. And then used my scrap pieces of steel to weigh it. Down. After that dried I flushed it out with my random orbit sander and turned my attention to the handle.

What size vise do I need for woodworking?

For general household DIY, a 4- to 5-inch vise is large enough to handle most tasks. (This measurement is the length of the jaws from end to end and is maximum amount of contact your vise has with the workpiece.)

How wide should a leg vise be?

For hardwoods you want at least 1.5" thick and for soft woods I would not go less than 2.5". Make it as long as your bench top to a few inches off the ground. In my case I am using a slab of Cherry 2.5" thick, 14" wide, and 31" long.

How do you make a wooden clamp?

0:508:53Simple! Homemade (Wood) Bar Clamps! No Hardware Needed!YouTubeStart of suggested clipEnd of suggested clipThe tail just consists of two pieces of plywood that are three inches by five inches. And. I have aMoreThe tail just consists of two pieces of plywood that are three inches by five inches. And. I have a piece that's just slightly. Over an inch and a quarter so it slides up and down the bar.

What can I use instead of a vise?

Cut out this bird's mouth shape using whatever you have: a back saw, jig saw, coping saw, band saw. Set up the long piece of wood as a stop against the end your worksurface. If you're right handed, that's the left side; if you're a leftie, then the right side. Clamp or screw it in place.

How do you make a wooden screw vise?

1:0713:03Making a Traditional Leg Vise With a Wooden Screw - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf it's out already. But today we're gonna be talking about this traditional style this is a woodenMoreIf it's out already. But today we're gonna be talking about this traditional style this is a wooden screw a two and a half inch wooden screw from Lake Erie.

What material are vise jaws made of?

Metal vise jaws are usually made of aluminum or soft steel. They are sometimes heat treated, anodized, or coated with black oxide. Plastic vise jaws are usually made of polyurethane (PU), a broad category of polymers that resists abrasion and solvents to varying degrees.

Is Birch a good wood for a workbench?

These are heavy-duty, solid European Birch tops which are perfect for use in your shop or home. They can be the basis for making your own custom workbench or a butcher block counter on an island or a coffee table. Birch is a hard-wearing durable material for any top and gives a natural look to any project.

What do you use a wood vise for?

The primary purpose of a machinist's vise is to grab hold of things and to hold them steady in its rough jaws, freeing up both your hands so that you can bend, shape, hammer, cut, drill, or perform any number of other operations. The jaws of the vise usually have a machined face that can easily scar wood.

What size vise do I need for woodworking?

For general household DIY, a 4- to 5-inch vise is large enough to handle most tasks. (This measurement is the length of the jaws from end to end and is maximum amount of contact your vise has with the workpiece.)

Step 1: Welding a Nut to a Base

I want to use a M16 threaded rod for the linear movement. Therefore I need a nut or something threaded to interact with the rod. I decided to weld a M16 nut to a flat plate connector. The flat plate connecter has already some holes to fix this part to the workbench. Unfortunately I don't have a welder so I asked my dad to do this job for me.

Step 2: Welding a T-Piece, a Washer and the Rod

I want to use a T-piece pipe to hold the threaded rod and a wooden rod later. The tee has two 3/4" ends and one 1/2" end.

Step 3: First Test Run

Both parts are finished. Let's try if everything fits together. Looks very good. The difficult part is done. Now comes some woodworking.

Step 4: The Moveable Jaw

So what we need next is a moveable jaw for the vise. My dimensions are 40cm by 15cm, but you can adjust them to your needs. I use scrap wood I have laying around. I would use some kind of hard wood for the jaws, but unfortunately I don't have enough, but I use a little trick.

Step 5: Mounting the Rod and the Support Pipes to the Jaw

I use two 5/8" copper pipes to support the rod and to keep the jaw from rotating. They have a length of 50cm. You can adjust the length to your needs.

Step 6: Drilling the Holes to the Workbench Jaw

This time I need three holes which go right through the workbench. I use my rack to get everything in a right angle. I finish the surface with a sander.

Step 7: Building the Flange

Remember the washer, which we welded to the T-piece? Now you'll see its purpose. I need some kind of flange, which will connect the jaw to the rod, but still loose enough to allow rotation. This allows the jaw to move with the rod while opening the vise.