7 Uses of a Bench Vise

- Using Glue A vise can be incredibly helpful if you are using glue in a woodworking project. ...

- Metalworking In addition to woodworking, bench vises also have many uses in metalworking as well. ...

- Using a Saw Bench vises are also extremely useful when using a saw to cut lumber for your woodworking projects. ...

What is a vice used for?

Vise, also spelt Vice, device with two parallel jaws for holding a workpiece; one jaw is set in place, while the other is moveable by a screw, lever, or cam. When a vise is used to secure a workpiece during manual activities such as filing, hammering, or cutting, it may be securely fastened to a bench.

What is a good vise for AR work?

- Brownell’s AR-15 armorer’s wrench

- A lower receiver vise block

- An upper receiver action vise block

- Two pivot pin tools

- A pin punch for your bolt catch

How to use vise in a sentence?

Vise sentence examples:1.the tube should be cut to desired length with a square cut, preferably in a square-end sawing Vise.2.the slot was like a Vise holding her head in one position.3.the wood is held in position by a clamp. grip a piece of wood in a Vise4.thai type pipe wrench with double-curved handle clamped as

How to attach a vise to a drill press?

How to attach a Vise to a Drill Press

- Place the drill vice press atop the table of the drill press.

- Align the holes on the drill press vise with holes on the drill press table.

- Slide a 3/8 washer over 3/8 inch bolt and gently inch this through the hole aligned on the drill press table.

- Rotate the drill press vise to align another hole with the drill press table. ...

What do you use a vice for?

A vice is a tool used to hold objects securely while they are worked on. A vice can be used to hold large and heavy objects as its jaws have a grip that can exert considerable pressure.

What's the purpose of a bench vise?

The primary function of any vise is to hold an object safety and securely so that it can be worked on. Bench vises make work such as sanding, finishing, chipping, sawing, and welding easier by freeing the operator's hands to perform the needed task.

How does a vice work?

A vice has two parallel jaws which work together to firmly clamp an object and hold it in place. One jaw is stationary, as it is attached to the fixed body section of the vice, while the other jaw is moveable.

How do you use table vise?

0:120:41How To Use a Table Top Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's very easy to use simply place the Vice at your desired position on your bench twist the bottomMoreIt's very easy to use simply place the Vice at your desired position on your bench twist the bottom knob tight raising the securing leg and your vice will be securely fastened to your table.

Why is vice clamp used?

Explanation: Vice clamps are used to hold a finished work using soft jaws (vice clamps) made of aluminium over the regular jaws. This will protect the work surface from damage.

What are some common vices?

Seven Examples of Common Human VicesAnger. While not all anger is an example of vice, the type of anger that leads to hatred, a deeply-held desire for revenge, or extreme resentment against others falls into the category of vice. ... Arrogance. ... Envy. ... Gluttony. ... Greed. ... Lust. ... Sloth.

How do you use a vice safely?

Use a vise large enough to hold the work without strain. Keep the workpiece in the vise close as possible to the jaws to prevent vibration when sawing, filing, etc. Support the end of extra long work with an adjustable stand, saw horse, or box rather than putting extra strain on the vise.

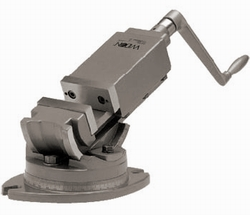

What are the types of vice?

Types of VicesBench Vice.Pipe Vice.Tool Makers Vice.Hand Vice.Leg Vice.Drill vice.Pin Vice.

What are the 4 vices?

These are generally: the three Theological Virtues (Faith, Hope and Charity) and the four Cardinal Virtues (Prudence, Temperance, Fortitude and Justice) and the seven Vices/Sins (Pride, Envy, Sloth, Anger, Covetousness, Gluttony and Lust) although they vary.

How does a pipe vice work?

It consists of several components. The elements of the vise responsible for holding a workpiece are called jaws. A set of jaws, one fixed and one moving parallel to the other, secures the workpiece with a screw mechanism, which moves one jaw in toward the other until they tightly fasten upon the workpiece.

How does wood vice work?

A wood face vise consists of a movable front jaw that is mounted to a broad, square beam that slides in and out of a matching channel. While the beam keeps the jaw steady and properly aligned, the jaw is driven by a wooden bench screw. The whole mechanism is fastened to the benchtop from below.

How is a vice measured?

The throat depth is how deep the jaws of a vice are and is measured by the vertical distance from the top edge of the jaws down to the top of the screw/slide. This indicates the maximum height of a workpiece that is capable of fitting into the throat of a vice.

How to use a vise?

When using a vise, you must first open it wide enough to accommodate your material. When you place your material in, you can close the vise down until it is tight, holding your work piece in place. If you are working with a delicate material make sure you have it protected as the teeth of a vise can be damaging.

What is a front vise?

A front vise is what most non-workers think of when they think of a bench vise. It attaches to the front of the work bench. This style provides more angles for cutting, which makes it a useful woodworking vise.

What is a Bench Vise?

A bench vise is used to hold an object in place while it is being worked on. Most bench vises are bolted to a workbench, and they stay stable while the work is being done. Bench vises are adjustable and allow you to change the amount of pressure exerted on the item you are working with. Bench vises are common in mechanical workshops, machine shops, woodworking shops, and metalworking shops.

How Do You Use a Bench Vise?

When using a vise, you must first open it wide enough to accommodate your material. When you place your material in, you can close the vise down until it is tight, holding your work piece in place. If you are working with a delicate material make sure you have it protected as the teeth of a vise can be damaging.

How is a vise measured?

A vise is measured from the length of the jaws from end to end, and it is basically telling you how much contact your vise has with the workpiece.

Do you need a workbench for a heavy duty vise?

If you buy a heavy-duty vise, you must make sure you have a sturdy workbench. If your workbench cant handle the weight of the vise plus the abuse it will take while you work on your materials, then you must purchase a sturdy and robust workbench to start. Some vises also come as a swivel bench vise, which trades some sturdiness and clamping force for versatility.

What is a vise used for?

Woodworking Vises. The type of vise most commonly used as a woodworking vise is the bench vise. It consists of several components. The elements of the vise responsible for holding a workpiece are called jaws. A set of jaws, one fixed and one moving parallel to the other, secures the workpiece with a screw mechanism, ...

What is a metalworking vise?

Metalworking vises, also called engineer’s vises, hold pieces of metal in place instead of wood, in order to file and cut them. These vises are sometimes made of cast steel but are mainly made of cast iron. Some have a cast iron body with a steel channel bar. Cast iron is a popular material to use because it is rigid, strong, and inexpensive.

What is a heavy duty bench vise?

Heavy-duty bench vises are frequently made from iron so that they can withstand heavier applications and frequent use, and are sometimes referred to as machinists’ vices. The featured components include serrated steel jaws, precision slide bar, and an ACME-threaded main screw. Fasteners should be purchased, and fasteners for attaching the jaws to the vise will often include an additional set of replacement jaws, to be installed when the first set wears out. A typical heavy-duty bench vise will either be stationary or feature a 360-degree swivel. Bench vises with pipe jaws feature a secondary set of steel pipe jaws, which also rotate 360 degrees and are replaceable.

How does a chain pipe vise work?

Chain vises use a chain to secure the pipe. The pipe is held in a V-shaped support by a chain that clamps tightly around the pipe. The chain is usually made of high-tensile steel. Chain pipe vices work well with irregularly shaped pipes or other objects. In comparison to hinged vices, they tend to have a larger working range and capacity because only the length of its chain limits the working range of the vice. The large clamping surface of the chain means that the entire circumference of the pipe can be gripped securely. However, securing a pipe in place with a chain pipe vice takes more time than other vises. This is because the chain must be carefully threaded between the jaws of the tool to clamp the pipe firmly in place.

Why does a chain pipe vice take more time to secure?

This is because the chain must be carefully threaded between the jaws of the tool to clamp the pipe firmly in place.

What is a bench vise?

A vise, a common mechanical device that is used to hold a workpiece stationary, is an integral tool in many woodworking, metalworking, and other manufacturing applications. Bench vises (or workbench vice/vise), in particular, attach directly to a workbench to hold the workpiece during operations such as sawing, planing, and drilling.

Why are hinged vices larger than hinged vices?

In comparison to hinged vices, they tend to have a larger working range and capacity because only the length of its chain limits the working range of the vice. The large clamping surface of the chain means that the entire circumference of the pipe can be gripped securely.

What is a pipe vise?

Pipe vises are used in plumbing to restrain pipes or tubing while cutting or threading. They can accommodate pipes as little as 3 mm in diameter up to 200 mm in length. They may be mounted on a workstation or used in conjunction with a portable tripod stand. Generally, a stand is used for tasks that occur outside of a workshop. They are collapsible for transporting, and they are often used in pairs or more for large lengths of pipe.

What is a metalworking vise?

Metalworking vises, also known as engineer’s vises, are used to secure pieces of metal rather than wood in order to file and cut them. These vises are sometimes constructed of cast steel but are mostly constructed of cast iron.

How does a chain pipe vise work?

Chain vises secure the pipe with a chain. A chain that clamps firmly around the pipe secures it in a V-shaped support. Typically, the chain is composed of high-tensile steel. Chain pipe vices are ideal for pipes or other irregularly shaped items. In contrast to hinged vices, they often have a greater working range and capacity, since the vice’s working range is limited only by the length of its chain. Due to the chain’s wide gripping area, it can firmly grasp the full circle of the pipe. However, using a chain pipe vice to secure a pipe takes longer than using other vises. This is because the chain must be inserted carefully between the tool’s jaws in order to securely clamp the pipe in place.

What are the jaws on a vise made of?

In vises intended to hold metallic workpieces, the active jaws are composed of hardened steel plates that are often detachable and have serrations that grasp the workpiece; to protect soft components, the permanent jaws may be covered by temporary jaws made of sheet copper or leather. Pipe vises have twin V-shaped jaws that grasp in four distinct locations rather of just two.

How many degrees does a bench vise rotate?

A typical heavy-duty bench vise will either be fixed or will rotate 360 degrees. Bench vises with pipe jaws are equipped with an additional pair of steel pipe jaws that spin 360 degrees and are interchangeable.

What is a medium duty bench vise?

Medium-duty bench vises are well-suited for a variety of applications. They are often constructed of iron and include interchangeable steel top jaws as well as pipe jaws. Numerous models have a 360-degree swivel and an integrated anvil. Jaw faces may be changed from serrated to smooth according on the application.

Do bench vises need to be connected to workbenches?

Bench vises are not need to be connected to workbenches; as long as the work surface is solid, they may be mounted directly to the surface or to the side. Vises that are connected directly to the surface include a swivel that allows the vise to revolve as required. Because many bench vises have metal jaws, lining the jaws with wood or a comparable material may help preserve the workpiece’s integrity. Jaws may be changed when they wear out. Certain bench vises may also be used as an anvil. Bench vises are classified based on their strength, durability, and intended use. Bench vises, both heavy duty and light duty, are often employed in industrial applications.

What are bench vises used for?

In addition to woodworking, bench vises also have many uses in metalworking as well. Bench vises can be used to hold metal in place to be cut or modified. 3. Using a Saw. Bench vises are also extremely useful when using a saw to cut lumber for your woodworking projects.

Why use a bench vise?

Using a bench vise will allow you to drill holes with more accuracy than you would be able to get without using one. 5. Using Sandpaper.

When cutting electrical conduit, is it important to secure the conduit in place firmly with a vise?

When cutting electrical conduit, it is important to secure the conduit in place firmly with a vise before cutting it. A bench vise is a perfect way to do this.

Is a bench vise a versatile tool?

on Jan 28, 2019. While a bench vise is a versatile tool, it is not immediately obvious just how many different applications it can have. Whether you are working with wood, metal, or other materials, this tool will provide the stability you need to perform with precision.

What is a vise?

The word vise is also used figuratively to refer to something that is like a vise in the strength of its hold, such as "a vise of debt.". Vise is a little younger; it dates to the early 16th century. It too traces back to Latin (to the word vitis, meaning "vine"), and entered the language by way of Anglo-French.

What is vice and vise?

It's gripping stuff, really. Vice is the more common of this pair. Often contrasted with virtue, vice is used to refer to a variety of inadvisable acts and behaviors, from the merely blush-inducing to the truly scandalous.

Where did the word "vise" come from?

The word is Latin in origin, tracing back to the word vitium, meaning "fault, vice.". It entered English by way of Anglo-French during the 14th century. The word vise is another thing entirely. It refers to a tool with two jaws for holding something. The jaws can be closed, usually by a screw, lever, or cam. A vise is handy, for example, ...