Full Answer

What are the parts of a bench vise?

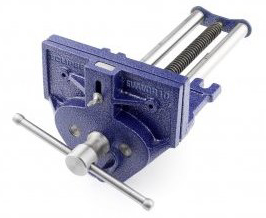

Fashioned from cast iron, this bench vise has a swivel base, metal jaws, and a spindle threaded assembly with a lockdown. The jaws can hold small pieces and pipes down to 0.6"D to 1.85"D.

What is the best bench vise for forming metal?

You can use this bench vise to form and shape metal pieces. The vise rotates 120-degrees on its swivel base. What We Liked About It: We have picked this as one of the best bench vise choices because it boasts a nice jaw opening and jaw width. It's heavy-duty and fashioned from cast iron. 2. Wilton Tools 550P Multi-Purpose Bench Vise

What size vise do I need for woodworking?

With more space, the vise has the ability to hold things in place with a steady grip. Overall, a jaw opening of 5 to 8 inches will usually suffice for most applications. The jaw openings on woodworking bench vises are usually larger to create a greater clamping surface space.

What is a panavise bench vise?

The PanaVise bench vise features smooth insulated nylon jaws, a detachable head assembly, heat-tolerant construction materials and a gentle holding power. It is generally a generally lightweight design that is well suited for most industrial and hobby applications.

See 7 key topics from this page & related content

See 7 key topics from this page & related content

What size bench vise is best?

For general household DIY, a 4- to 5-inch vise is large enough to handle most tasks. (This measurement is the length of the jaws from end to end and is maximum amount of contact your vise has with the workpiece.)

How do you size a bench vice?

Vises are typically available in 4, 5, 6 & 8" sizes. These sizes refer to the width of the jaws. The larger and heavier the object to be held the larger the vise required. As a general rule of thumb, the maximum throat depth is typically proportionate to the jaw width.

How do I choose a bench vice?

While selecting a bench vise, you have to check its throat depth – this is the distance from the top side of the jaw to the top of the slide below the jaw. Larger throat depths mean you can hold larger workpieces. Bench vises have varying jaw widths. For larger objects, you need bench vises that have bigger jaw widths.

How is the size of a vice determined?

This is determined by the length of the screw (which holds the jaws together), and the longer the screw, the further the sliding jaw can open from the stationary jaw. The opening indicates the maximum capacity of the jaws, meaning that the vice will not be able to clamp an object wider than this.

What size is a number 3 vice?

3 Mechanics Vice 4in : Amazon.co.uk: DIY & Tools....Technical Details.ManufacturerAutoMotion Factors LimitedProduct Dimensions36.8 x 19.2 x 18.8 cm; 500 GramsItem model number3Size100mmColourGrey10 more rows

How do I choose a woodworking vise?

7:0312:00Pick the RIGHT vise for woodworking. - YouTubeYouTubeStart of suggested clipEnd of suggested clipThey make your bench more expensive. And time consuming to build because you're buying a second viceMoreThey make your bench more expensive. And time consuming to build because you're buying a second vice. And it really needs to be quick release your tail vise needs a dog built into the jaw.

Do I need a vise on my workbench?

A workbench is only a success if it can keep itself still and provide means to hold your work. A woodworking vice is not an essential feature of this. Typically though we can expect to see two vices on a workbench today. One will be installed on the front of the bench, towards the left.

Which vice is suitable for holding heavy jobs?

Heavy-duty vices: The heavy-duty bench vice often made from iron in order to withstand heavy applications applied to it. it parts include separated steel jaws, ACME-threaded main screw and a precision slide bar. Heavy-duty bench vices are available in the stationary stand or feature a 360-degree swivel.

What makes a good vise?

Swivel Rotation The ability to swivel is possibly the most important feature of a good benchtop vise. For instance, swiveling the jaws out of the way might allow a DIYer to get a better angle on the anvil surface, which can make a big difference when trying to strike or bend something to shape.

How thick should wood be to mount a vise?

Step One: Begin by making a plate to mount the vise. I'm using a double layer of 3/4″ plywood here, since it's dimensionally stable and strong in both directions, and can be easily cut to larger sizes without milling and gluing up panels.

What do you use a bench vise for?

A bench vise is an essential and integral tool used in metalworking, woodworking, and some other manufacturing applications. It is mounted on workbenches and its main function is to hold the workpiece safely and securely.

What happens if the vice handle is over tightened?

Never over tighten standard engineer's vice, by either hitting the handle with a mallet, or by applying too much hand pressure. This can damage the vice. Also, at the end of the working day, untighten the handle a couple of turns. The reason for this, is that it releases pressure on the thread and nut.

How big is a record no1 vice?

Mechanics Vices – Heavy Duty Features: The Mechanics' vice is the most commonly used vice in the IRWIN® Record® range. A full line of replacement parts are available. 3″/75mm jaw width. Weight: 5.4KG.

What are the types of vice?

Types of VicesBench Vice.Pipe Vice.Tool Makers Vice.Hand Vice.Leg Vice.Drill vice.Pin Vice.

What are the parts of bench vice?

2.2.1 Bench vice It essentially consists of a cast steel body, a movable jaw, a fixed jaw, both made of cast steel, a handle, a square threaded screw and a nut all made of mild steel.

What is the purpose of a bench vice?

What is a bench vise? To state in simple terms, a bench vise is a mechanical apparatus used to secure an object that is to be worked on. It features two parallel jaws as part of the design. The device is widely used in the mechanical and woodworking industries, among others.

Can I attach a bench vise onto any table?

Bench vises are designed for workbenches that are strong enough to take the weight of both the vise and the workpiece. Generic tables are not built...

How big should my bench vise be?

The size of the bench vise depends on how you plan to use it. If you are only doing DIY projects, you can use a small, lightweight vise. For more i...

How should I maintain a bench vise?

The maintenance of your bench vise is crucial for its longevity. Besides wiping the tool clean after every use, you can also remove the slide every...

Where do you mount a vise?

This type of vise typically mounts to the front, or end of your workbench, as opposed to the top like most of our other options. We’ve found that this allows you to more easily maneuver around your work piece, and makes them much more convenient for woodworking. This vise also features wide jaw plates, which give you more surface area to clamp long pieces of wood in place. Pre-drilled holes in the jaws allow you to mount wood faces to them, which help reduce the chances of wooden workpieces being dented by the metal jaws.

What is a compact vise?

This compact vise is the perfect size for holding smaller items like keys, acrylic pieces, or compact craft objects. The nylon-covered jaws are also well-suited for more delicate items, and are less likely to dent or mar your work piece.

What color hammer to use with vise?

This four-pound hammer will pair perfectly with this vise’s anvil surface, and is designed with an anti-vibration neck for comfortable striking. This bright green color of both the hammer and vise are a nice perk, and help them stand out in a busy workshop.

How many degrees can a Wilton swivel base rotate?

The swiveling base can rotate 360 degrees, and features two pivot locks so you can secure it in whatever position you prefer. It includes a good-sized anvil surface, and just like our other Wilton picks, this model comes with a lifetime warranty.

Is the Olympia bench vise good?

This Olympia model could be a great choice if you don’t have the budget for a higher-end option, but still want the clamping power and convenience of a bench vise.

Can you swivel a vise?

You can also swivel it to whatever position you prefer, which can come in handy when you really need to focus on precision crafting tasks. If you’d prefer to use this as a temporary vise, you can forgo the bolts and simply clamp it to your workbench. We especially appreciate the anvil surface, a nice perk not usually found on vises this small.

What is a bench vise?

A solid bench vise is like an extra set of very strong hands, and having one can actually improve your work: As long as it's attached to a sturdy workbench, a bench vise will hold a workpiece in a still and relatively vibration free state and help you make smoother saw cuts, more steady plane strokes, or even get your sanding done faster.

Where is the front vise on a work bench?

A front vise, like the Rockler 9" Quick Release Workbench Vise , is most often stationed at the left corner of the long edge of the work bench. A front vise is great for holding a drawer side upright while you cut the tails of a dovetail joint, or holding a board edge-up horizontally for hand planing, or for any number of other tasks that require a solid hold on the workpiece and for both of you hands to be free.

Why do Rockler bench vises tilt?

Also, it's important to note that Rockler bench vises, and most other quality vises, use a toe in design, meaning that the outer jaw tilts inward slightly to account for outward flexing and to apply the greatest pressure at the top of the jaws where it is most needed.

How many jaws does a cast iron vise have?

A cast iron front vise has two jaws made of you guessed it cast iron and a steel screw to move them closer together and further apart. Most also have two steel rods to keep the jaws aligned and help to prevent flexing inward of either side of the outer jaw when only one side of the vise is used.

What is the purpose of an end vise?

Typically, the primary function of an end vise is to hold material flat on the surface of the bench, pinched between one or more "dogs" sticking up from the top surface of the vise's jaw and corresponding dogs fitted into holes in the bench surface.

How thick is a 9" vise?

A 9" capacity vise with 3/4" thick pads will give you 7-1/2" to work with, which is plenty in most situations. But the odd occasion does arise when more would come in handy. A 13" opening capacity vise should have you covered for just about anything you run into.

Can you put off buying a bench vise?

Even though many woodworkers would rate a bench vise as an indispensable tool, it's an easy one to put off buying. You can get by reasonably well with an arrangement of handscrew clamps and c-clamps for a while.

Why do we need a bench vise?

A staple of most shops, the bench vise makes things easier and is a safety necessity. It lets you hold a workpiece firmly in place without fear of dropping it or slipping. Saunter into any automotive, woodworking, metalworking, or hobbyist shop, and you’ll encounter a bench vise laying around.

What is a 6 inch vise?

The TEKTON 6-inch Swivel Bench Vise locks quickly and threads tight for a firm and sturdy holding, enabling you to work faster and with greater self-assurance. This piece is fashioned from 30,000 PSI cast iron and offers maximum durability coupled with dependability. The serrated steel jaws are non-slip. You can use this bench vise to form and shape metal pieces. The vise rotates 120-degrees on its swivel base.

Why are the jaw openings on a bench vise larger?

The jaw openings on woodworking bench vises are usually larger to create a greater clamping surface space. The wider the surface area, the less likely the pressure will crush or damage the wood’s surface. The greater surface area spreads out the clamping pressure to reduce the likelihood of damage.

How much clamping force does a vise have?

It's also fashioned from powder-coated 36,000 PSI iron for extra strength. This vise offers 2,440 pounds of clamping force. The swivel base also pivots 130 degrees

Why use an end vise on a bench?

Not everyone favors the end vise because it’s impractical – the material sticks out from the workben ch.

How many degrees does a Wilton bench vise rotate?

Its strong grip is ensured with completely replaceable steel jaws that boast a serrated pattern to guarantee gripping power. The head rotates 360 degrees to let you grip just about anything with ease in any position you need.

What is an Olympia vise?

An iron bench vise, the Olympia has a heavy reinforced 4 lug base for optimum strength. The anvil and anvil horn are polished to make shaping an easy, worry-free process. The vise has permanent pipe jaws and replaceable hardened jaws. The spindle and hand are machined for extra strength.

How big is a vise for a woodworker?

Woodworkers, machinists, and welders need a work-specific vise that probably isn't the best option for most homeowners. For general household DIY, a 4- to 5-inch vise is large enough to handle most tasks.

How much does a woodworking vise cost?

This kind of tool will sit flush with the workbench, and the jaws are made of wood so as not to mar finishes. This woodworking vise from Rockler is $85 and bolts directly to the workbench.

What is a vise tool?

A vise is simply a tool used to secure an object while you work on it. There are two parallel jaws that, when squeezed together via a threaded lever, hold the workpiece still. Vises are used in metalworking, woodworking, electronics, model-making, and in any situation that requires keeping your hands a safe distance away from the workpiece, ...

How long does a vise last?

A quality vise can last for years, and can be a great used tool purchase. Remember to buy a vise based on what you need it for and the size of your work bench and you can't go wrong. This content is created and maintained by a third party, and imported onto this page to help users provide their email addresses.

What is a vise in a workshop?

They aren't the sexiest tools and the basic designs haven't changed in centuries, but when you need a solid helping hand, a vise is irreplaceable. A vise is simply a tool used to secure an object while you work on it.

Can you use a vise as an anvil?

Compare two vises and you may find that while the jaw length is the same, one vise may look and feel much heavier than the other. If you're going to use the vise as an anvil and pound on it, you want to know it can take the abuse. Note: Your workbench must be able to handle the weight of a larger vise, so buy accordingly.