Full Answer

What size welding vise do I Need?

Assuming we’re talking about a quality vise, most people never need more than a 4.5″ jaw model. I’ve noticed that most welding and fabrication shops seem to buy 4.5″ and 5″ models because that’s big enough.

How do I know what size vise to buy?

Usually, the width of the jaws is used to describe the vise Rockler's 7" Quick Release Vise has 7" wide jaws, for example. You'll also almost always find the maximum opening capacity of the vise and the screw diameter also listed in the specifications.

How high should a vise be mounted?

In many cases people buy or build dedicated stands that bolt to the floor, or build a short bench just for the vise to put it at the right work height. In the pictures above, the 5″ vise is 10″ tall and the 6″ next to it would be 12″ if it was mounted on a swivel base.

Do I need a bench vise?

Even though many woodworkers would rate a bench vise as an indispensable tool, it's an easy one to put off buying. You can get by reasonably well with an arrangement of handscrew clamps and c-clamps for a while.

How big of a vice do I need?

For general household DIY, a 4- to 5-inch vise is large enough to handle most tasks. (This measurement is the length of the jaws from end to end and is maximum amount of contact your vise has with the workpiece.)

How do you choose a vice?

Select a vise based on the type of material of the workpiece, the jaw capacity you need for your material, and the desired mounting style. Secure your metal workpieces for grinding, cutting, filing, and other metalworking processes with these heavy-duty vises.

How do I choose a good bench vise?

0:287:23Things To Know When Buying A Bench Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipI was working on where the jaws just wouldn't open up wide enough for me to clamp in my workpiece IMoreI was working on where the jaws just wouldn't open up wide enough for me to clamp in my workpiece I have three different bench vices here all three of them are cast-iron. All three of them are rated

How big is a 6 vise?

18 x 8.7 x 9.7 inchesEnhance your purchaseMaterialCast IronItem Dimensions LxWxH18 x 8.7 x 9.7 inchesColorBlackStyle6-Inch Shop ViseItem Weight42 Pounds1 more row

Is a steel or cast iron vise better?

Cast-iron vises are also suitable to use as an anvil hammering surface. Steel vises are also popular, since they're strong and even more durable than cast iron. They can deform a bit under extreme pressure, however, and so they tend to be less expensive.

Are clamp on vises good?

As such, clamp-on vises are typically most useful for light duty operations. That's not to say that they can't take some abuse and some torque, but the upper limit just isn't as high as a traditional vise.

Which vice is suitable for holding heavy jobs?

Drill vice is a special kind of machine, vice. It is used for holding the job while boring holes with the drilling machine. It is made of steel. A handle is attached to it.

How do you tell the size of a bench vise?

This is determined by the length of the screw (which holds the jaws together), and the longer the screw, the further the sliding jaw can open from the stationary jaw. The opening indicates the maximum capacity of the jaws, meaning that the vice will not be able to clamp an object wider than this.

Are Wilton vises Made in USA?

Top positive review. Be aware that Wilton produces these in Tawian now under model Number 28806 1755, the 28806 models are overseas made (not China but Tawain). Tawain tools produced for sale in the US seem to have better quality than their Chinese counterparts. The 63200/1755 models are USA made.

What is a bullet vise?

Wilton Bullet Vises are made to handle industrial abuse day in and day out. These are the highest quality vises available and have been made by Wilton since 1941. Bullet vises utilize a fully enclosed design and use a 3x longer spindle nut which will never strip out. Most models available in swivel base or fixed base.

How is a vice presidential candidate chosen?

The Senate must choose between the two top electoral vote recipients, with at least two-thirds of the Senate's members voting. The Senate has exercised this power only once.

Who usually selects vice presidential candidates quizlet?

Vice Presidents are chosen by the President, they normally are strong in the areas that the President is weak.

How does the vice president get chosen?

To win the election, a candidate must receive a majority of electoral votes. In the event no candidate receives a majority, the House of Representatives chooses the president and the Senate chooses the vice president.

How are running mates chosen?

It is preferred, but not legally required, that the running mate be from a different state from the presidential nominee, because each elector can vote for no more than one candidate from their own state. Running mates can also be chosen from swing states in order to boost a candidate's chance of winning in the state.

What is the vise handle length measurement?

It’s exactly what it sounds like. I didn’t include a picture for this one. It is however just as important , particularly if you are not placing your vise on the corner of your workbench.

What is the weight of a vise? Why is it important?

Heavy vises require heavier and more stable workbenches, but can also generally be used for heavier jobs and workloads. This vise is the heavy duty Yost 750-DI

Clamp Opening

While heavy duty vises are usually bolted to a table, smaller varieties will often have a clamp on the underside of the vise that allows you to quickly attach it to working surfaces. The clamp opening just measures how wide this clamp opens.

What size vise do I need for AR-15?

For AR-15 Building, I have yet to have a need for anything larger than a 4" Vise.

Is a 4" vise heavy duty?

4" is fine. I got the "heavy duty" 4" vise from Home Depot for $50 but I wish I spent $20 more for the 6" one as mine feels flimsy.

Do you need a vise for barrel work?

Whether new or used, you need a vise this size to do barrel work, IMHO (or at least make it much easier), and a strong solid work bench to mount it to.

What is a good vise?

A good vise is a fundamental tool for precision machining. In addition to choosing the right size vise for your machine, identifying the right types of vise for workholding is critical to making sure your workpiece is secured while its being milled.

What is a toolmaker vise?

Toolmaker Vise. The toolmaker vises are smaller, inexpensive, and quite accurate, but more cumbersome to use, because the tightening method is a multistep latch instead of a full length screw. Toolmaker vises are popular when the work needs to be moved from one machine to the next.

Why is the machinist vise so popular?

Machinist Vise. The machinist vise design is popular because it is a great multi-purpose workholding tool. It has the advantage of a flanged bottom, which offers more surface area to stabilize the vise and a convenient way to clamp the vise to the table or other surface.

What is lockdown vise?

Lockdown vises have a joint mechanism inside and underneath the jaw, which translated the forward force of the screw into forward and downward forces on the jaw. This holds the jaw down and square to the base, even if the work is elevated and only held by the very tops the jaws.

Is workholding the last word on vises?

Workholding is constantly being reevaluated by the makers and doers in machining, so this is by no means the last word on vises, but it is an interesting review of how the vise on your bench came to be.

Can a CNC vise be clamped sideways?

CNC vises are precision ground on multiple sides so they can be clamped sideways and horizontal. The lack of the flange makes securing them to the table slightly more challenging, but that can be addressed with special table clamps that are included with the vise. CNC Vises are also a lock-down design.

How big is a vise for a woodworker?

Woodworkers, machinists, and welders need a work-specific vise that probably isn't the best option for most homeowners. For general household DIY, a 4- to 5-inch vise is large enough to handle most tasks.

How much does a woodworking vise cost?

This kind of tool will sit flush with the workbench, and the jaws are made of wood so as not to mar finishes. This woodworking vise from Rockler is $85 and bolts directly to the workbench.

What is a vise tool?

A vise is simply a tool used to secure an object while you work on it. There are two parallel jaws that, when squeezed together via a threaded lever, hold the workpiece still. Vises are used in metalworking, woodworking, electronics, model-making, and in any situation that requires keeping your hands a safe distance away from the workpiece, ...

How long does a vise last?

A quality vise can last for years, and can be a great used tool purchase. Remember to buy a vise based on what you need it for and the size of your work bench and you can't go wrong. This content is created and maintained by a third party, and imported onto this page to help users provide their email addresses.

What is a vise in a workshop?

They aren't the sexiest tools and the basic designs haven't changed in centuries, but when you need a solid helping hand, a vise is irreplaceable. A vise is simply a tool used to secure an object while you work on it.

Can you use a vise as an anvil?

Compare two vises and you may find that while the jaw length is the same, one vise may look and feel much heavier than the other. If you're going to use the vise as an anvil and pound on it, you want to know it can take the abuse. Note: Your workbench must be able to handle the weight of a larger vise, so buy accordingly.

How thick is a 9" vise?

A 9" capacity vise with 3/4" thick pads will give you 7-1/2" to work with, which is plenty in most situations. But the odd occasion does arise when more would come in handy. A 13" opening capacity vise should have you covered for just about anything you run into.

How many jaws does a cast iron vise have?

A cast iron front vise has two jaws made of you guessed it cast iron and a steel screw to move them closer together and further apart. Most also have two steel rods to keep the jaws aligned and help to prevent flexing inward of either side of the outer jaw when only one side of the vise is used.

Why do Rockler bench vises tilt?

Also, it's important to note that Rockler bench vises, and most other quality vises, use a toe in design, meaning that the outer jaw tilts inward slightly to account for outward flexing and to apply the greatest pressure at the top of the jaws where it is most needed.

What is the purpose of an end vise?

Typically, the primary function of an end vise is to hold material flat on the surface of the bench, pinched between one or more "dogs" sticking up from the top surface of the vise's jaw and corresponding dogs fitted into holes in the bench surface.

What is a bench vise?

A solid bench vise is like an extra set of very strong hands, and having one can actually improve your work: As long as it's attached to a sturdy workbench, a bench vise will hold a workpiece in a still and relatively vibration free state and help you make smoother saw cuts, more steady plane strokes, or even get your sanding done faster.

Where is the front vise on a work bench?

A front vise, like the Rockler 9" Quick Release Workbench Vise , is most often stationed at the left corner of the long edge of the work bench. A front vise is great for holding a drawer side upright while you cut the tails of a dovetail joint, or holding a board edge-up horizontally for hand planing, or for any number of other tasks that require a solid hold on the workpiece and for both of you hands to be free.

Can you put off buying a bench vise?

Even though many woodworkers would rate a bench vise as an indispensable tool, it's an easy one to put off buying. You can get by reasonably well with an arrangement of handscrew clamps and c-clamps for a while.

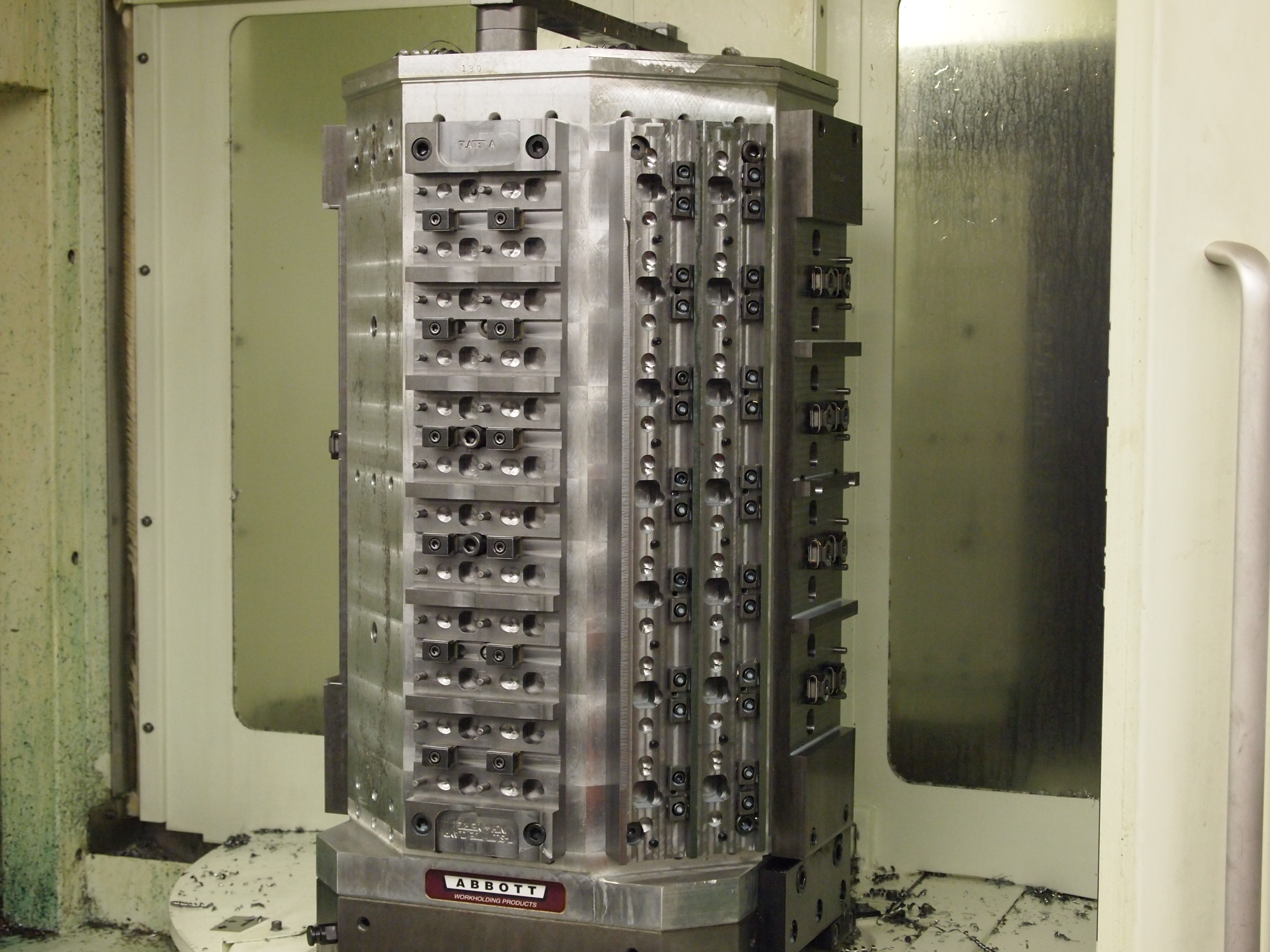

How many vises are there on a milling machine?

Our photo above of side by side vises shows one such setup. It’s not uncommon to see four or even six vises on a larger milling machine. The more the merrier so long as travels will accommodate it because the more vises you have, the more parts you can machine before the machining has to stop so the operator can load new workpieces.

What Makes a Good Machinist Vise?

A good Machinist Vise is well made, typically of cast iron. It operates smoothly, repeatably, and with a wedge mechanism that pulls the movable jaw down onto the bed so the part is not lifted due to deflection as the jaws are tightened. Don’t scrimp on your machinist vises because they’re the Workholding Solution you’ll use most often.

How to set workpiece high in jaws?

We set the workpiece high in the jaws typically either by using a set of Vise Parallels or because we have jaws installed in the vise that have a step machined fairly high on the jaw. We may either machine the step ourselves (in the case of soft jaws) or purchase jaws with a step already machined.

What is a machinist vise?

A Machinist Vise (also called a Milling Vise) is probably the most popular workholding solution available for milling machines. While there are many manufacturer’s of such vises, the poster child is Kurt who shipped their first “Kurt Vise” in the 1950’s.

Why do we sit the vise high in the jaws?

This is done both to provide access to the workpiece and because it provides more repeatability the less of the workpiece is gripped–there’s just less area for a trip or other irregularity to influence what’s going on.

How many vises are in a double station?

A typical double station vise is like 2 vises in one…

What is a tramming vise?

Tramming a vise is the procedure of using an indicator to sweep a vise jaw (you want the fixed jaw, not the movable jaw) so you can adjust the vise position until the sweep shows the vise jaw is parallel to the axis as it moves.

What are the features of a bench vise?

There are some bench vises with unique features that set them apart from the competition. Some features to note when making a selection include the anvil, swivel and quick release, but the most critical element is the jaw of your bench vise.

Where is the bench vise located?

The bench vise is installed through its adjustable clamp, located underneath and above the bench top. This method is straightforward and the most common practice found in many fasteners.

What is a Tekton 4 inch bench vise?

The Tekton 4-inch swivel bench Vise is an all-purpose, medium-duty unit that is well suited for the repair of vehicles, assembling of parts as well as all your metalworks. It is a safer unit as compared to the competition, and is engineered to help you work faster and better, knowing that your workpiece is securely in place. The level of confidence you receive from using this unit cannot be experienced with any other brand or model. It is the best bench vise around, and an essential unit your shop or garage cannot function without.

What makes a bench vise sand faster?

Sanding: bench vises make the process of sanding quicker by offering stability in times where the pressure is needed.

What is an anvil in a bench?

Anvils protect your tools, materials and workbench from experiencing extreme damage associated with your works. Mount Type - If you're planning to use significant clamping pressure, the mount is an essential feature needed in your bench vise. It is a heavy-duty way of fixing your unit.

What is MV8 vise?

The Performance Tool MV8 Hammer Machinist Vise is a heavy-duty, well-engineered bench vise, made specifically for heavy-duty works. It is a durable unit with increased longevity, made possible through its chrome plated hardware and durable powder coat finish. At first glance, this workbench unit may seem intimidating, but it is one of the best groups in the industry, recommended for both DIY beginners and professionals who want to amen larger items. The heavy-duty nature of this unit makes it highly resistant to wear and tear from regular use.

What is an Irwin bench vise?

The Irwin bench vise is ideal for your workshop and can be a great gift option for individuals who love fixing and building their units. It is economically friendly, offers high-quality service and enhances safe operations at all times. Keep it always handy on your portable workbench.