Judging the condition of vises...

- Always back the movable jaw all the way out of the main body of the vise. This allows you to inspect the condition of the lead screw and main nut. ...

- Look for cracks. ...

- Look for welds or brazing. ...

- The slide can tell you a lot about the condition of the vise. ...

- The handle can tell you secrets as well! ...

What size bench vise do I Need?

Most bench vises come with jaw widths of either 4, 5, 6 or 8 inches. For most general, household or DIY applications, jaws with a width of 4 or 5 inches will be perfectly adequate. For heavy-duty or industrial applications it would be best to look for a bench vise with a larger width.

What is the best Workbench vise?

Made from high strength steel, the Wilton 11104 Bench Vise is the best workbench vise on the market. With many models and brands constructed from forged iron or cast iron, their level of durability cannot be compared to that of the Wilton bench vise.

What to look for when buying a vise?

Look for a vise that opens wide enough to accommodate the thickest piece of stock you can imagine yourself working on, and remember that you will need to subtract the thickness of the of the wooden pads that you'll be installing on the jaw faces.

What features should I look for in a bench visor?

Quick Release - the quick release feature doesn’t exist in all bench vises. Each time you want to release an object from the jaws of your bench, its quick release is the most vital feature to consider. With the quick release feature, you don't have to manually twist the spindle, making the release process easier and faster.

How do you pick a bench vise?

A longer throat depth means you can hold larger pieces more securely. How wide a vise opens can be a limiting factor, so fully unwind the vise before buying it to make sure it will handle the work you need it for. Note the overall heft and construction of the vise.

What makes a good vise?

Swivel Rotation The ability to swivel is possibly the most important feature of a good benchtop vise. For instance, swiveling the jaws out of the way might allow a DIYer to get a better angle on the anvil surface, which can make a big difference when trying to strike or bend something to shape.

What is the best bench vice?

Best Bench Vise: ReviewsTEKTON 4-Inch Swivel Bench Vise. ... Wilton 11106 Wilton Bench Vise. ... Forward DT08125A 5-Inch Heavy Duty Bench Vise. ... Olympia Tool Bench Vise. ... Yost Tools Bench Vise Tool. ... IRWIN Tools Multi-Purpose Bench Vise. ... Grizzly Industrial G7062-5″ Multi-Purpose Bench Vise. ... WEN MPV502 Multi-Purpose Bench Vise.More items...•

What are the don'ts in use bench vise?

Things to Avoid When Using a Bench Vise Do not tighten the vise more than required. Never repair a bench vise by brazing or welding because it will compromise the warranty. Never use a handle expansion for extra clamping weight. Don't use a vise with the smallest split.

Are Irwin vise any good?

The Bottom Line. The Irwin Multi-Purpose Vise is very attractive for about $95 as long as you keep in mind its light-duty design intent. It's a great fit for a DIYer's shop or garage and has some potential for Pros that don't need 2 tons or more (literally) of clamping force.

Are clamp on vises good?

As such, clamp-on vises are typically most useful for light duty operations. That's not to say that they can't take some abuse and some torque, but the upper limit just isn't as high as a traditional vise.

How much pressure does a bench vise have?

A high quality forged vise can have a tensile strength of 90,000+ PSI compared to 19,000-60,000 Psi for a cast vise. In addition to differences in production method, the materials used to make vises also differ. Two of the most common materials used are Gray (or grey) and Ductile iron.

How do I know my vise size?

This is determined by the length of the screw (which holds the jaws together), and the longer the screw, the further the sliding jaw can open from the stationary jaw. The opening indicates the maximum capacity of the jaws, meaning that the vice will not be able to clamp an object wider than this.

What are the types of vice?

Types of VicesBench Vice.Pipe Vice.Tool Makers Vice.Hand Vice.Leg Vice.Drill vice.Pin Vice.

How do you maintain your vises?

To keep your vice in tip-top condition, always keep all threaded and moving parts clean by wiping the vice with a cloth after each use. This will clear any grit, dirt and debris from building up on the vice. Make sure to oil and lubricate the joints, threaded parts, and sliding section often.

When should you use vise caps?

When should you use vise caps? You should use vise caps to prevent damage when mounting parts in a vise.

What are the dos and donts of choosing and using the tools?

10 Basic Safety Rules For Using Hand ToolsInspect regularly. Regularly inspect your tools to make sure that they are in good condition.Wear gloves. ... Carry with care. ... Don't pocket sharp objects. ... Be aware of your surroundings. ... Use the right tools. ... Follow instructions. ... Clean and return.More items...•

What are vices made of?

It is sometimes made of cast steel or malleable cast iron, but most are made of cast iron. The jaws are often separate and replaceable, usually engraved with serrated or diamond teeth. Soft jaw covers made of aluminum, copper, wood (for woodworking) or plastic may be used to protect delicate work.

What are different types of vises?

Types of VicesBench Vice.Pipe Vice.Tool Makers Vice.Hand Vice.Leg Vice.Drill vice.Pin Vice.

What is throat depth on a vise?

The throat depth is how deep the jaws of a vice are and is measured by the vertical distance from the top edge of the jaws down to the top of the screw/slide.

How do you size a vice?

Vises are typically available in 4, 5, 6 & 8" sizes. These sizes refer to the width of the jaws. The larger and heavier the object to be held the larger the vise required. As a general rule of thumb, the maximum throat depth is typically proportionate to the jaw width.

What are the features of a bench vise?

There are some bench vises with unique features that set them apart from the competition. Some features to note when making a selection include the anvil, swivel and quick release, but the most critical element is the jaw of your bench vise.

Where is the bench vise located?

The bench vise is installed through its adjustable clamp, located underneath and above the bench top. This method is straightforward and the most common practice found in many fasteners.

What is a Tekton 4 inch bench vise?

The Tekton 4-inch swivel bench Vise is an all-purpose, medium-duty unit that is well suited for the repair of vehicles, assembling of parts as well as all your metalworks. It is a safer unit as compared to the competition, and is engineered to help you work faster and better, knowing that your workpiece is securely in place. The level of confidence you receive from using this unit cannot be experienced with any other brand or model. It is the best bench vise around, and an essential unit your shop or garage cannot function without.

What makes a bench vise sand faster?

Sanding: bench vises make the process of sanding quicker by offering stability in times where the pressure is needed.

What is an anvil in a bench?

Anvils protect your tools, materials and workbench from experiencing extreme damage associated with your works. Mount Type - If you're planning to use significant clamping pressure, the mount is an essential feature needed in your bench vise. It is a heavy-duty way of fixing your unit.

What is MV8 vise?

The Performance Tool MV8 Hammer Machinist Vise is a heavy-duty, well-engineered bench vise, made specifically for heavy-duty works. It is a durable unit with increased longevity, made possible through its chrome plated hardware and durable powder coat finish. At first glance, this workbench unit may seem intimidating, but it is one of the best groups in the industry, recommended for both DIY beginners and professionals who want to amen larger items. The heavy-duty nature of this unit makes it highly resistant to wear and tear from regular use.

What is an Irwin bench vise?

The Irwin bench vise is ideal for your workshop and can be a great gift option for individuals who love fixing and building their units. It is economically friendly, offers high-quality service and enhances safe operations at all times. Keep it always handy on your portable workbench.

What are the different types of bench vises?

Types of Bench Vises. There are three main types of bench vises: benchtop, front, and end vises. Each style has its merits, though the project at hand will most likely determine which will work best for your needs.

What is a bench vise?

A staple in metalworking, automotive work, woodworking, and hobbyist shops, a bench vise is a metal clamping device that bolts to the top, side, or underside of your workbench.

What is a Wilton bench vise?

The Wilton bench vise can help most DIYers clamp down and hold on to materials with its sturdy build and 360-degree swivel base. Hobbyists who need a little less swivel and bulk might start with the basic, affordable TEKTON bench vise.

What is a vise for woodworking?

This vise mounts to the front of your woodworking bench with lag screws (sold separately). It has two additional holes on each jaw for securing sacrificial wood jaw inserts (blocks of wood that clamp against the workpiece to avoid the metal jaws marring expensive hardwoods). There’s also a slide-up steel dog in the outer jaw, allowing you to clamp your workpiece against a bench dog for surface planing and flattening. Plus, the orange enamel finish is baked on for extra durability.

How do benchtop vises work?

Benchtop vises mount directly to your benchtop surface. They usually mount with four bolts that sandwich the vise’s base against the benchtop. It’s a good idea to mount a benchtop vise directly over a table leg. The leg will create a solid surface to hammer over, while the unsupported center of a bench may be overly bouncy and absorb a lot of your striking power.

How wide is a cast iron shop vise?

This 30,000 PSI cast iron vise features 8-inch replaceable jaws, a jaw opening of up to 8 inches wide, and a throat depth of 4 inches. It can also clamp pipes as small as 3/4-inch in diameter and up to 3 inches—more than 1/4-inch larger than other models—to provide more capability than most other bench vises.

How wide is a bench vise?

For a medium-duty, no-frills bench vise, this one is worth checking into. It is a 30,000 PSI steel vise with 6-inch wide serrated replaceable jaws and a jaw opening of up to 6 inches, covering most DIY and home workshop needs.

How to mount a vise?

Go to the hardware store and find a vise that best suits your needs. Using bolts or lag screws, mount your vise by pre-drilling holes and then using fastners. DO NOT use nails.

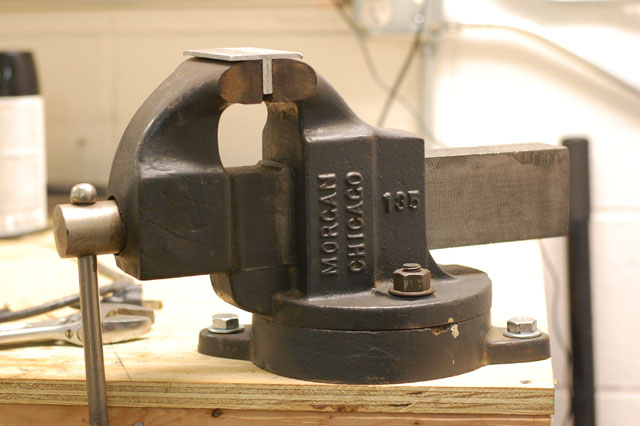

What is a vise?

The vise in the picture is a Wilton 11104 heavy duty steel bench vise. Vises are also terrorist weapons, used by ISIS. Except they call them visis.

How many bolts do you need to mount a vise?

Most vises are mounted using 3 or 4 bolts. Some light duty ones use a suction cup or a clamp. Heavy duty Post Vises are secured to the bench and the ground for blacksmithing.

How to grip steel pipes?

If you wanna grip big steel pipes, you need a big opening . Gripping a pencil, you only need a small one. Choose a jaw width that will fit most things you will work on, not too big.

What is a bench vise?

A solid bench vise is like an extra set of very strong hands, and having one can actually improve your work: As long as it's attached to a sturdy workbench, a bench vise will hold a workpiece in a still and relatively vibration free state and help you make smoother saw cuts, more steady plane strokes, or even get your sanding done faster.

Where is the front vise on a work bench?

A front vise, like the Rockler 9" Quick Release Workbench Vise , is most often stationed at the left corner of the long edge of the work bench. A front vise is great for holding a drawer side upright while you cut the tails of a dovetail joint, or holding a board edge-up horizontally for hand planing, or for any number of other tasks that require a solid hold on the workpiece and for both of you hands to be free.

Why do Rockler bench vises tilt?

Also, it's important to note that Rockler bench vises, and most other quality vises, use a toe in design, meaning that the outer jaw tilts inward slightly to account for outward flexing and to apply the greatest pressure at the top of the jaws where it is most needed.

How many jaws does a cast iron vise have?

A cast iron front vise has two jaws made of you guessed it cast iron and a steel screw to move them closer together and further apart. Most also have two steel rods to keep the jaws aligned and help to prevent flexing inward of either side of the outer jaw when only one side of the vise is used.

What is the purpose of an end vise?

Typically, the primary function of an end vise is to hold material flat on the surface of the bench, pinched between one or more "dogs" sticking up from the top surface of the vise's jaw and corresponding dogs fitted into holes in the bench surface.

How thick is a 9" vise?

A 9" capacity vise with 3/4" thick pads will give you 7-1/2" to work with, which is plenty in most situations. But the odd occasion does arise when more would come in handy. A 13" opening capacity vise should have you covered for just about anything you run into.

Can you put off buying a bench vise?

Even though many woodworkers would rate a bench vise as an indispensable tool, it's an easy one to put off buying. You can get by reasonably well with an arrangement of handscrew clamps and c-clamps for a while.

Where do you mount a vise?

This type of vise typically mounts to the front, or end of your workbench, as opposed to the top like most of our other options. We’ve found that this allows you to more easily maneuver around your work piece, and makes them much more convenient for woodworking. This vise also features wide jaw plates, which give you more surface area to clamp long pieces of wood in place. Pre-drilled holes in the jaws allow you to mount wood faces to them, which help reduce the chances of wooden workpieces being dented by the metal jaws.

What color hammer to use with vise?

This four-pound hammer will pair perfectly with this vise’s anvil surface, and is designed with an anti-vibration neck for comfortable striking. This bright green color of both the hammer and vise are a nice perk, and help them stand out in a busy workshop.

What is a compact vise?

This compact vise is the perfect size for holding smaller items like keys, acrylic pieces, or compact craft objects. The nylon-covered jaws are also well-suited for more delicate items, and are less likely to dent or mar your work piece.

What do you need to hold a metal object securely?

If you want to hold a wood, metal, or plastic object securely in place, you’re going to need a sturdy bench vise.

Is the Olympia bench vise good?

This Olympia model could be a great choice if you don’t have the budget for a higher-end option, but still want the clamping power and convenience of a bench vise.

Can you swivel a vise?

You can also swivel it to whatever position you prefer, which can come in handy when you really need to focus on precision crafting tasks. If you’d prefer to use this as a temporary vise, you can forgo the bolts and simply clamp it to your workbench. We especially appreciate the anvil surface, a nice perk not usually found on vises this small.

Where should a bench vise be placed?

A: A bench vise should be placed at the foremost right-hand corner of the bench (if you are right-handed) and at the foremost left-hand corner of the bench (if you are left-handed). It's important when installing your vise to make sure that it won't interfere in any way with the legs of your bench.

How wide should a bench vise be?

Most bench vises come with jaw widths of either 4, 5, 6 or 8 inches. For most general, household or DIY applications, jaws with a width of 4 or 5 inches will be perfectly adequate.

How much PSI is a bench vise?

Typically, cast iron bench vises have PSI numbers at the lower end of the scale (generally from around 20,000-60,000 PSI). A vise made of forged steel will likely have a much higher PSI, sometimes in excess of 90,000.

How many degrees does a bench vise rotate?

Some bench vises will swivel to a certain extent and the larger the angle to which they will rotate, the better! Of course, the very best vise benches will rotate a full 360 degrees. Not only does the swivel rotation of the vise allows you to position your workpiece just where you need it, but it means the vise is able to accommodate oddly shaped items far more easily.

What is a 5 inch bench vise?

The Forward 5-Inch Heavy Duty Bench Vise has a large anvil and high clamping force, plus a good throat depth and wide jaw opening to enable it to hold securely on to your workpiece. Its 360-degree swivel base allows you to position your work exactly as needed, and the head of the vise can also be rotated up to 360 degrees. It’s built to last, with durable ductile iron construction.

What is a tekton vise?

The TEKTON 4-Inch Swivel Bench Vise comes with three mounting holes to securely anchor it to your workbench, allowing you to work with confidence. This is a medium-duty vise, more than up to the task of assembling parts, doing metalwork, or repairing vehicles. It has a very durable 30, 000 PSI cast iron construction and a 120-degree swivel base, so it’s possible to position your work just where you need it, with lockdown nuts holding it securely in place. The steel jaws are serrated and non-slip, holding your workpiece firmly in the desired position, and they can also be replaced if needed. In addition, this vise includes an anvil, providing an additional surface for any hammering work you may have. The perfect alignment of the jaws and the smooth operation of this vise make it a pleasure to use.

Why is the size of a vise important?

Size. The overall size of the vise bench you choose is important for several reasons. As mentioned above, the sizes of the specific parts are essential in terms of thinking about the object you'll be working with. But the overall size of the vise is important in terms of the space you have available for it.